SEWAGE TREATMENT

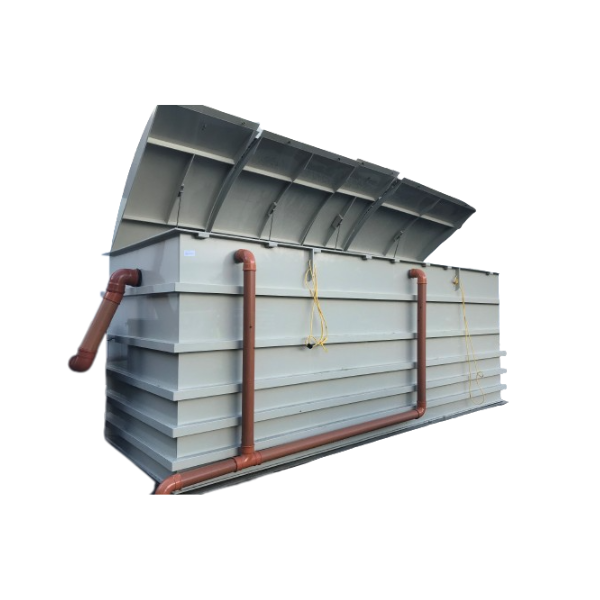

Home Sewage Treatment Plant: Tricel Novo

OVERVIEW

Regarding your house, you want the best equipment available on the market. You want something that will last, require minimal maintenance and allow you to make the most out of your money. The same reasoning applies to your home sewage treatment plant. No matter your needs, we have the product you are looking for: the Tricel Novo.

This market-leading solution is robust, cost-saving, easy to install, and trustworthy. Its purification process requires three stages, all codependent from one to another. The magic happens inside the tank, throughout three different chambers.

KEY BENEFITS OF A TRICEL NOVO PLANT:

- Compact: about five m² of floor space (for five or six population equivalents);

- Lightweight: (200 to 300 kg): easy and inexpensive installation (sewage treatment plant with concrete tank weights more than two tons);

- Efficient: effective treatment, no risk of clogging;

- Adaptable: suitable for all types of terrain (difficult ground, the presence of groundwater);

- Reliable: long life (20 to 40 years, whereas the spreading of a traditional die must be replaced every 10 to 20 years);

- Tested and certified: for structural strength, water tightness, durability and treatment efficiency, adhering to European Standard EN12566- 3 (like all sewage treatment solutions manufactured by Tricel)

If you have any questions, feel free to call us

VISIT OUR VIRTUAL SHOWROOM

How does a Tricel Novo work?

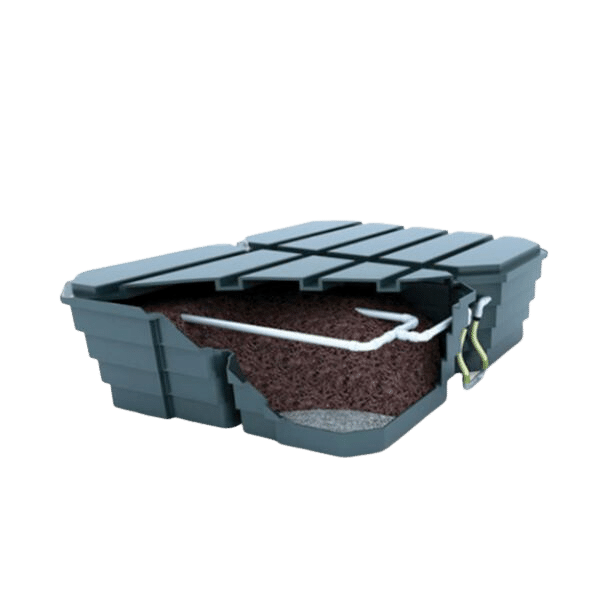

As a home sewage treatment plant, the Tricel Novo operates its purification system in three stages, ensuring high effluent quality. It uses a straightforward process that is one of the most efficient and technically advanced in the sewage treatment industry. To understand how the Novo works, remember that every stage of the treatment process has its chamber.

Primary settlement chamber: In this first stage of sewage treatment, the solids are separated from liquids (up to 70%). They are going to the bottom of the tank whilst the soon-to-be treated water flows to the next zone of treatment.

The aeration chamber: Natural bacteria are being solicited throughout this second stage. While they are sustained by an air compressor in the top section of the unit, they are fed by the waste that flies with the liquid when leaving the first chamber.

The final settlement chamber: Once mostly cleared up, the liquid goes to the final settlement chamber, the last stage of the purification process. It helps to slow the liquid’s velocity and furnishes a last filtering effort for the last impurities. Those go to the bottom of the tank and then return to the first chamber, thanks to a sludge return system. The now-treated water is ready to be evacuated, meeting the required standards established by your local environmental authorities.

Tricel Novo: Key features & benefits

The compression moulding process is one of the most technologically advanced features available on the market. Components are manufactured under heat and high pressure. They have a competitive strength and durability over standard GRP tanks or PE tanks.

SMC is a unique material in the sewage treatment industry with Tricel SMC tanks operating in some of the harshest climatic conditions for over 50 years with no defects.

Tricel’s ceramic diffuser will last twice as long as all standard competitors rubber equivalents. It is a cost-saver in both call out fees and replacement parts.

No concrete backfill for installation on most sites which allows you to save up to €400 over lower quality GRP/plastic competitors.

There are no moving parts or pumps in the plant which is ensuring reliable operation during the treatment process and minimal running costs.

Tricel Novo plants are designed with a shallow invert to limit both installation and time costs.

Standards and certification

The design and the purification process of the Tricel Novo wastewater treatment systems are approved by the European Standard EN12566-3, which ensures compliance across the EU. After completion of nine months of thorough testing in an independent laboratory, the systems have also been awarded the CE Mark.

Interact with our Home Sewage Treatment Plant

How to interact with the tank

- Click on the numbers to see the annotations.

- You can also switch between the treatment process stages (yellow circle at the bottom left-hand corner) and the anatomy of the Novo (green circle at the bottom left-hand corner).

- To view in Virtual Reality (VR), click the square at the top right-hand corner and simply scan the QR code with your phone.

- In order to check the dimensions, click on the spanner icon.

- To download an image of the Novo, click on the camera icon (top right-hand corner)

50 YEARS IN BUSINESS

A highly successful multinational corporation with over 50 years’ valuable industry experience

SEWAGE TREATMENT PLANTS

Plants available for all capacities, from 1PE up to 50PE. Free advice on request.

FAST DELIVERY

On-time delivery is a core requirement of our successful business operations

Recent projects with HOME SEWAGE treatment plant

Extensive industry experience, manufacturing since 1973.

Tricel manufacture deliver & install sewage treatment plants across a wide range of industry sectors throughout Ireland & the UK. The company also provide import/export services for our international clients. This top quality material offers outstanding capabilities including long life, durability and is a cost-effective solution for sewage treatment even in the harshest environments.

Tricel has installed many of its Tricel Novo Sewage Treatment Plants across the UK.

Check some of our projects by clicking on the button below.

Articles you might be interested in

MEET OUR TEAM

To find a technician in your area, visit our page

TALK SEWAGE TREATMENT

To speak to one of our agents online, click here

ASK FOR A QUOTE

Request a free quote today to have a quote that meets your project!

Frequently Asked Questions

WHAT IS THE DIFFERENCE BETWEEN A CESSPOOL, A SEWAGE TREATMENT PLANT AND A SEPTIC TANK?

A cesspool is a simple storage vessel with an inlet and no outlet. It’s a sealed storage vessel; all the water coming in stays within the tank. The advantage is it doesn’t need an outlet. The disadvantages are: there is no treatment, the tanks are huge, and it needs regular emptying. Everything which has gone in must be sucked out. Ideal for sites which have got very infrequent use (Sheppard huts, for example).

Septic tank

A septic tank has an inlet and an outlet; it’s a simple overflow system. See how a septic tank works here. The advantages of the septic tank are there is no mechanic and no electricity requirement for it to work. The disadvantages are you are discharging dirty water, and untreated sewage effluent, as a tiny breakdown has occurred in the tank. You can only release water to a drainage field for the water to go through the subsoil to treat the water.

Sewage treatment plant

A sewage or package treatment plant has an inlet and an outlet; the wastewater is treated inside the tank. Aeration is provided inside the tank for the aerobic bacteria to feed on the waste and remove it from the liquid. The advantages are the wastewater is treated and can be discharged to a watercourse.

Many package treatment plants are available on the market:

- Trickles filters

- Rotating Biological Contactors (RBC)

- Mobile media bio-reactors

- Activated Sludge systems

- Sequence Batch Reactor systems (SBR)

- Fixed Bed Systems (like the Tricel Novo)

ARE THERE ANY SEWAGE TREATMENT PLANT REGULATIONS TO BE AWARE OF?

UK sewage treatment plants must comply with EN 12566-3 2005 regulations.

You should also hire a professional to install your sewage treatment system. For any sewage treatment plants you intend to install, you should also check your local guidelines to determine if planning permission is required.

HOW DO SEWAGE TREATMENT PLANTS WORK?

A sewage treatment plant is where domestic wastewater and sewage are treated. The sewage treatment plants break down organic matter through the primary settlement and aeration chambers. Sewage treatment plants require little maintenance and have low running costs, and sewage effluent is discharged into drainage fields or watercourses.

WHAT IS THE QUALITY OF THE WASTEWATER PRODUCED?

For example, the required standards are 20:30:20 for BOD, SS, and NH4.

Tricel® has achieved an 11:16:9 result during independent testing.

HOW LONG DOES IT TAKE FOR THE PLANT TO BEGIN OPERATING?

In order for the biomass to reach its optimum purification, it may take up to 16 weeks.

IS THE TREATED WASTEWATER REUSABLE?

You may be able to discharge directly into a watercourse or to a percolation area depending on your region. Find out which option is best for you by contacting your local council.

WHAT SIZE SEWAGE PLANT DO I NEED?

The sewage treatment plant’s size depends on the effluent volume from your house. It is determined by the number of people using the system, which is calculated based on the number of bedrooms in your home. If you need further information, contact our team.

WILL I NEED TO EMPTY (DESLUGING) MY SEWAGE TREATMENT PLANT?

Occasionally, your sewage treatment plant will need to be emptied due to the accumulated sludge inside – usually once a year. The frequency of emptying your treatment plant depends on its size and usage. See our dedicated page about desludging septic tanks and wastewater treatment plants.

WHY DOES THE USE OF RISERS MATTER?

1) to prevent surface water from entering the tank and overloading the system as this can inhibit growth of the bacteria and could reduce the effluent quality.

2) to prevent water getting into blower housing which can harm the control panel and the air blower.

Learn more about Tricel Novo risers.

Get in touch