frequently asked questions

FAQ - Frequently asked Questions about Stormwater Management Systems

To speak to one of our agents online about Frequently asked questions, click here

Find below the list of most Frequently asked questions regarding Stormwater Management Systems (FAQ – Questions about Stormwater Management Systems) and the Tricel range of reliable solutions.

Stormwater MaNAGEMENT questions

An attenuation system provides a long-term solution for mitigating the risk of flooding caused by water runoff during prolonged rainfall. These systems include a flow control chamber specifically designed to manage the volume of water discharged into nearby sewer systems or natural watercourses, such as rivers or reservoirs.

Historically, attenuation systems have been positioned beneath car parks or within access roads in high-volume residential developments.

The proposed storm drainage system offers advantages such as minimizing disruptions and reducing carbon footprints. However, disadvantages include higher initial investments and ongoing maintenance costs.

Unlike a soakaway system, underground floodways can be positioned much closer to a building. The critical consideration is ensuring that the building load or foundation load does not impact the tank. Ideally, if you were to draw a 45-degree angle from the foundation, that line should not intersect the system. The exact placement may vary based on the tank’s depth, but generally, they can be situated in close proximity to the building.

To accurately size a stormwater attenuation or soakaway tank, several key factors beyond volume are crucially important.

Firstly, the tank’s dimensions—specifically its length, width, and height—play a significant role in determining necessary components such as base plates and ventilation services. These dimensions are essential for designing a system that fits within the site’s constraints and operational needs.

Secondly, providing a drainage drawing offers a comprehensive understanding of the project’s layout and requirements. This drawing aids in precise calculations for the tank’s capacity and ensures accurate pricing for materials and installation.

Additionally, knowing the tank’s location, whether it’s situated under a park, driveway, or heavily trafficked area, is critical. Different locations may require specific design considerations, such as robust plate systems to withstand loads from vehicles or pedestrians.

If a drainage drawing is not available, providing accurate dimensions of the tank is essential. However, additional information about site conditions, soil properties, and intended usage may still be required for detailed calculations and optimal design.

To Conclude

In conclusion, achieving precise sizing for a stormwater management system necessitates detailed information on tank dimensions, location considerations, and ideally, a comprehensive drainage drawing. This approach ensures the implementation of an appropriate and effective solution tailored to the specific requirements of the project

When selecting the best stormwater system for your project, consider the following key factors:

- Stormwater System Application

- Sizing

- Footprint

- Cover Depth

- Base Preparation

- Stormwater System Construction Equipment

- Backfill

- Product Material

Stormwater System Total Installation Cost

Tricel Nero Range questions

The QuadroControl ST system shaft is designed to seamlessly integrate into modular block structures measuring 0.80 meters in both length and width. It serves multiple functions, including as an inspection shaft or ventilation point within the system, particularly effective when fitted with shaft covers that include ventilation openings.

The assembly features half elements that are straightforward to install on-site. Depending on the configuration, a cone is used for a full block shaft setup, while a roof slab is employed for a half block shaft configuration. Additionally, a sidewall grid is included as needed, based on its placement within either a storage or infiltration module.

Rigofill modules are efficiently delivered stacked on pallets measuring 1.60 meters by 0.80 meters. Each pallet contains 68 half elements, sufficient for assembling 34 modules. Typically, the factory stacks two pallets on top of each other for shipment.

Additionally, sidewall grids and supporting grids, along with roof slabs (required only for half blocks), are separately packaged on individual pallets. This packaging ensures organized and systematic delivery of components for assembly on-site.

EN 17152-1 introduces the first-ever product standard for storage and infiltration modules across Europe, marking a milestone in November 2019. It was accompanied by test standards for both short-term compressive strength (EN 17150) and long-term compressive strength (EN 17151).

This development is significant as it establishes a standardized European test methodology, allowing for the assessment and comparison of long-term compressive strength for the first time.

Over time, this standard is anticipated to gradually replace national approvals or serve as the foundational framework for test requirements in obtaining approvals across European jurisdictions.

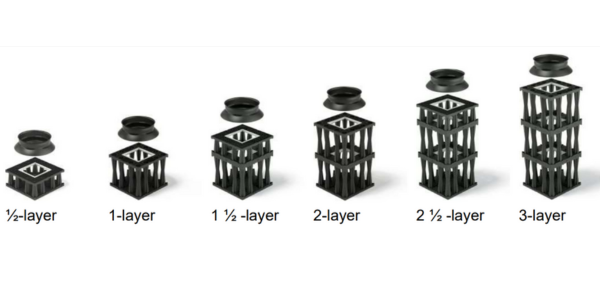

Rigofill storage and infiltration systems offer exceptional design flexibility, characterized by minimal constraints on length and width. The square 800 mm block layout enables seamless adaptation to virtually any configuration. With block heights of 660 mm for full blocks and 350 mm for half blocks, these systems can be constructed in various sizes to accommodate both single-layer and multiple-layer configurations.

This adaptability allows for tailoring the system to meet specific on-site requirements. In areas with high groundwater levels or low permeability soil, shallow-depth systems are preferred for effective water management.

Conversely, in soils with good permeability, taller and denser systems offer advantages and can be constructed accordingly to maximize space utilization.

Overall, Rigofill systems optimize design flexibility to suit diverse soil conditions and project needs, ensuring efficient stormwater management and utilization of available space.

CCTV inspection using state-of-the-art technology is the most effective method for assessing the condition of Rigofill modules. This approach enables thorough examination for final acceptance or subsequent evaluations, ensuring confidence and safety for authorities, engineers, construction firms, customers, and operators.

Rigofill ST modules are designed with a cross-shaped tunnel configuration, which enhances camera accessibility and allows for thorough inspection and maintenance in four dimensions. This design feature facilitates comprehensive examination and ensures the system’s operational integrity over time.

An underground floodway functions by directing excess flood or stormwater from the surface into subterranean tunnel facilities. These flood tunnels are built in stages and are typically located in urban areas where conventional river channelization is not feasible due to existing infrastructure constraints.

Attenuation systems function as a simple method for storing excess water, collecting water from multiple inlets such as pipes and channel drains, typically with a single outlet. Acting as a reservoir, the tank allows water to accumulate, preventing downstream drains from becoming overloaded during intense storms. The outlet often includes a flow control device, such as an orifice plate or vortex flow control, to manage the rate of water discharge. Tank size is determined by factors such as rainfall intensity, surface area, and considerations for climate variability.

Well-designed tanks should consistently manage the site’s water volume effectively, ensuring reliable performance under varying weather conditions.

Manuals & Specifications

View and download our brochure and technical information

Contact Us

Arrange a callback or email enquiry