TRICEL NERO RANGE - STORMWATER MANAGEMENT

Tricel Hydrostor - Stormwater attenuation systems

Tricel introduces the Hydrostor stormwater chambers, a high-performance solution within the stormwater attenuation systems range, available in four sizes designed to meet diverse site-specific needs.

These chambers provide an environmentally friendly approach to underground water management, promoting groundwater recharge and conserving land resources.

Our extensive range ensures compatibility with various performance requirements, project footprints, and construction budgets, offering versatility for a wide range of applications.

Introduction

Stormwater attenuation systems represent innovative solutions aimed at mitigating the effects of urbanisation on water resources by effectively controlling stormwater runoff.

These systems are engineered to temporarily store excess rainwater, enabling gradual release into the environment. This approach helps reduce the risk of flooding, erosion, and pollution.

Hydrostor, part of Tricel’s lineup, consists of underground stormwater chambers specifically designed to efficiently manage stormwater runoff across diverse environments. With customizable sizes and a strong focus on environmental sustainability, Hydrostor optimises land use while contributing to groundwater replenishment. It serves as a versatile and dependable solution for sustainable water management practices.

Tricel Hydrostor Range

Discover stormwater attenuation systems

Hydrostor HS290

Installed Storage Capacity*: 4.66 m3 /chamber

Height : 1,511 mm

Width : 2,554 mm

Unit Length : 1,317 mm

Installed Length : 1,227 mm

Weight : 56.7 kg

Chambers/Pallet : 10

Material : Polypropylene

Mfg. Process : Injection Molding

Special Features : Integrated Handle

ASTM Standards : Meets or Exceeds

Hydrostor HS180

Installed Storage Capacity*: 5.0 m3 /chamber

Height : 1,156 mm

Width : 1,976 mm

Unit Length : 2,253 mm

Installed Length : 2,167 mm

Weight : 57.6 kg

Chambers/Pallet : 19

Material : Polypropylene

Mfg. Process : Injection Molding

Special Features : Integrated Handle

ASTM Standards : Meets or Exceeds

Hydrostor HS75

Installed Storage Capacity*: 2.12 m3 /chamber

Height : 754 mm

Width : 1,300 mm

Unit Length : 2,210 mm

Installed Length : 2,160 mm

Weight : 31 kg

Chambers/Pallet : 33

Material : Polypropylene

Mfg. Process : Injection Molding

Special Features : Integrated Handle

ASTM Standards : Meets or Exceeds

Hydrostor HS31

Installed Storage Capacity*: 0.88 m3 /chamber

Height : 406 mm

Width : 864 mm

Unit Length : 2,220 mm

Installed Length : 2,170 mm

Weight : 15 kg

Chambers/Pallet : 90

Material : Polypropylene

Mfg. Process : Injection Molding

Special Features : Low Profile Chamber

ASTM Standards : Meets or Exceeds

* Assuming 40% void volume of backfill with 230 mm bedding & 300 mm cover for HS290 and HS180, and 150 mm bedding & 150 mm cover for HS75 and HS31

How to install stormwater attenuation systems like Tricel Hydrostor?

Installation steps for stormwater attenuation systems

Preparation

Excavate the site to the required depth and dimensions, ensuring proper slope and alignment for drainage.

Chamber Placement

Install the Hydrostor chambers according to the project specifications, ensuring proper spacing and alignment.

Connection

Connect the chambers using integral connectors for simplified assembly, ensuring a secure and watertight fit.

End Caps and Manifolds

Install end caps and pipe manifolds as needed to complete the system, ensuring proper flow and connectivity.

Pretreatment Options

Consider incorporating pretreatment options if required for specific project needs, such as sediment filtration or pollutant removal.

Safety Measures

Ensure safe on-site handling by utilizing integrated handles and following proper lifting techniques.

Final Checks

Conduct a final inspection to verify proper installation, alignment, and connectivity of the Hydrostor system.

By following these steps meticulously, you can effectively install a Tricel Hydrostor system to manage stormwater runoff while promoting environmental sustainability.

Images of Hydrostor installations

Preparation of the pipe hole

Tricel Hydrostor module installation

Pipe installation

Representation of a Hydrostor module delivery

Tricel Hydrostor module installation

Tricel Hydrostor key features ?

Performance

- Engineered from high-performance polypropylene.

- Meets or exceeds ASTM F2418 product standard and ASTM F2787 design standard.

- Complies with AASHTO H20 live load and HL93 design load requirements.

- Utilizes state-of-the-art injection molding technology for exceptional structural performance

System Design

- Maximizes land use while minimizing environmental impact.

- Provides a smaller footprint and lower installed cost compared to similar chambers.

- Features integral connectors for easy assembly.

- Access our design tool at Prinsco.com/HydroStor-Resources.

- Available as part of a comprehensive solution, including end caps, pipe manifolds, and pretreatment options.

Handling

- Equipped with integrated handles for safe on-site handling.

- Sturdy yet lightweight, facilitating safe transport and placement by two people.

- Includes a specially designed pallet for hassle-free handling.

- Maximizes stacking density to minimize on-site staging footprint

Meet our team

To find a technician in your area, visit our page

TALK STORMWATER MANAGEMENT

To speak to one of our agents online, click here

ASK FOR A QUOTE

Request a free quote today to have a quote that meets your project!

Tricel Nero Range of Products

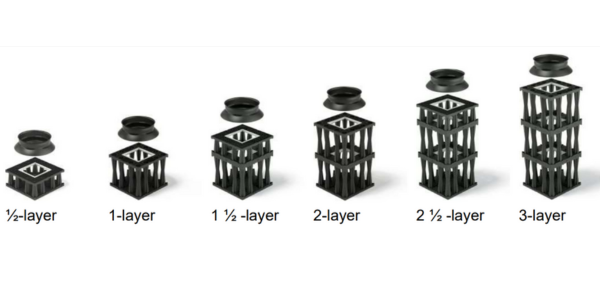

Tricel Crates

The Tricel crate system offers versatile components for the infiltration, retention, and storage of stormwater runoff. Ideal for smaller space/footprint.

Tricel Chambers

Tricel chambers offer a sustainable underground stormwater management solution that enhances groundwater recharge. Great for sites with a high water table.

50 YEARS IN BUSINESS

A highly successful multinational corporation with over 50 years’ valuable industry experience

STORMWATER MANAGEMENT

Different systems available for all projects. Free advice on request.

Technical Expertise

We have a expert and trained team ready to help your project.

Frequently Asked Questions

Why do you need attenuation tanks

An attenuation system provides a long-term solution for mitigating the risk of flooding caused by water runoff during prolonged rainfall. These systems include a flow control chamber specifically designed to manage the volume of water discharged into nearby sewer systems or natural watercourses, such as rivers or reservoirs.

How close can stormwater attenuation tank be to a building?

Unlike a soakaway system, underground floodways can be positioned much closer to a building. The critical consideration is ensuring that the building load or foundation load does not impact the tank. Ideally, if you were to draw a 45-degree angle from the foundation, that line should not intersect the system. The exact placement may vary based on the tank’s depth, but generally, they can be situated in close proximity to the building.

What are critical factors to consider with stormwater?

When selecting the best stormwater system for your project, consider the following key factors:

- Stormwater System Application

- Sizing

- Footprint

- Cover Depth

- Base Preparation

- Stormwater System Construction Equipment

- Backfill

- Product Material

Stormwater System Total Installation Cost

How do flood tunnels work ?

An underground floodway functions by directing excess flood or stormwater from the surface into subterranean tunnel facilities. These flood tunnels are built in stages and are typically located in urban areas where conventional river channelization is not feasible due to existing infrastructure constraints.

How does an attenuation tank work?

Attenuation systems function as a simple method for storing excess water, collecting water from multiple inlets such as pipes and channel drains, typically with a single outlet. Acting as a reservoir, the tank allows water to accumulate, preventing downstream drains from becoming overloaded during intense storms. The outlet often includes a flow control device, such as an orifice plate or vortex flow control, to manage the rate of water discharge. Tank size is determined by factors such as rainfall intensity, surface area, and considerations for climate variability.

Well-designed tanks should consistently manage the site’s water volume effectively, ensuring reliable performance under varying weather conditions.