SEWAGE TREATMENT

What is under the Tricel Novo green lid?

Home » Wastewater Treatment » What is under the green lid?

As a Tricel Novo owner or a potential buyer, you might wonder what is under the green lid. Here’s a complete guide to help you maximise your Tricel solution. The green lid should also make you feel more secure and confident about what to do if troubleshooting is needed.

If you have any questions, feel free to call us

VISIT OUR VIRTUAL SHOWROOM

Understanding the Tricel Novo

At Tricel, making a difference should be a priority for each one of us. As a leader in the industry, we ensure that the solutions we can provide you will respect this mindset and go above and beyond it. With our Tricel Novo, we developed a modern, advanced, simple, yet efficient system that will allow you to treat your wastewater. No matter where your effluents are coming from – dwellings or businesses- we have you covered. Suppose our sewage treatment plant is known for being our best-seller. In that case, it is mainly because of its technology and discretion..

This is the Tricel Novo

Stage 1: The primary settlement chamber

This is where some anaerobic breakdown takes place for the first time. The wastewater is introduced, and the solids drop to the bottom, separating itself from the liquid.

Stage 2: The aeration chamber

The next stage of sewage treatment involves an aerobic breakdown in the aeration chamber, where masses of naturally occurring bacteria inhabit specially designed filter media.

These bacteria are sustained with air, continuously supplied from a purpose-built pump in the unit’s top section (look into the ‘what is under the green lid’ section). As the liquid flows slowly through the filter media, the bacteria feed on the waste and remove it from the liquid.

Stage 3: Final settlement chamber

In the last stage of wastewater treatment, the liquid flows from the aeration chamber into the final settlement chamber. Suspended sludge consisting of bacteria is carried with the liquid into the settlement chamber. It settles to the bottom of the chamber. A continuous sludge return system pumps it back to the primary settlement chamber. The remaining treated liquid meets the required standard to pass out of the Tricel system safely.

What is under the green lid?

As part of our Tricel Novo’s design, we have this mysterious green lid on top of our system. It also became a landmark for those who own one of our solutions, as this is the only part that will be visible once fully installed.

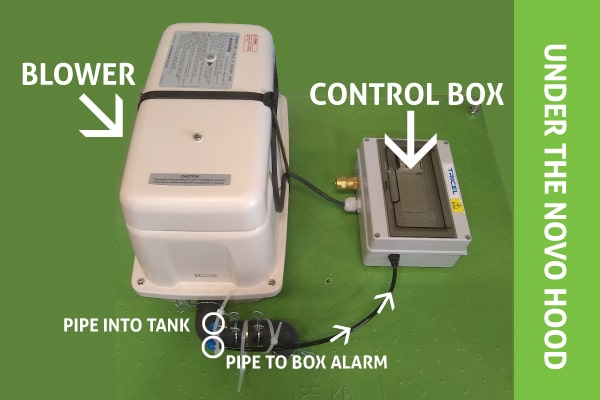

Inside the green lid, we have:

1 x blower

1 x control box

2 x pipes connected to the blower pipe. One goes to the control box and monitors the pressure and the alarm. The second goes into the tank and powers the sludge return system previously mentioned.

The electricity goes into the orange/yellow connection on the Control Box.

Our range of off-main drainage solutions

Tricel Novo Sewage Treatment Plant

Durable & long lasting SMC tank, shallow dig tank, easy installation (Plug and Play), long life components.

Tricel Phosphorus Removal

Tricel PhosClear is a ready-to-install system that reduces Phosphorus wastewater without using chemicals.

Tricel Maxus Sewage Treatment Plant

Commercial plant. Submerged Aerated Filter (SAF) technology. Ideal for every project over 50 Population Equivalent.

Tricel Vento

Septic Tank

Shallow dig tank, strong & robust underground tank, no electrical or moving parts.

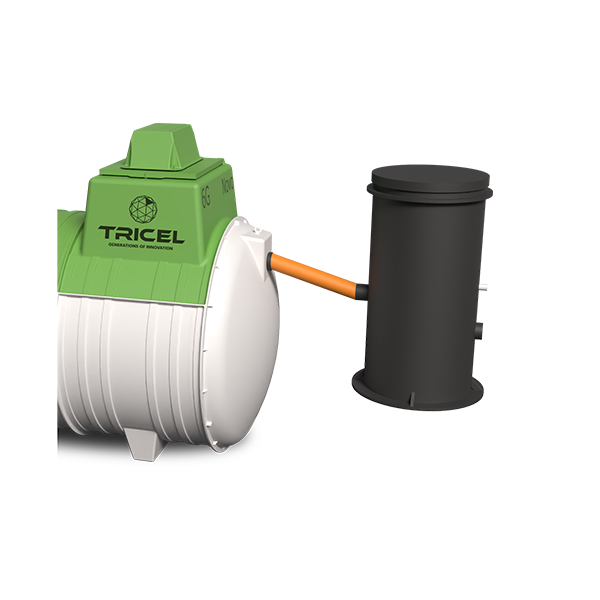

Tricel Tero Tertiary System

Next Generation tertiary wastewater treatment unit with proven E.Coli treatment capabilities.

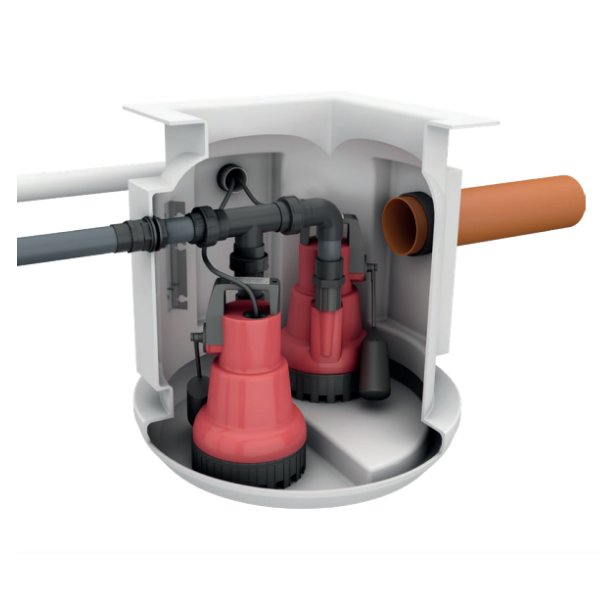

Tricel Pumping

Stations

Pump fluids from one place to another where gravity drainage cannot be used, easy and trouble-free installation.

Tricel Novo: Key features & benefits

The compression moulding process is one of the most technologically advanced features available on the market. Components are manufactured under heat and high pressure. They have a competitive strength and durability over standard GRP tanks or PE tanks.

SMC is a unique material in the sewage treatment industry with Tricel SMC tanks operating in some of the harshest climatic conditions for over 50 years with no defects.

Tricel’s ceramic diffuser will last twice as long as all standard competitors rubber equivalents. It is a cost-saver in both call out fees and replacement parts.

No concrete backfill for installation on most sites which allows you to save up to €400 over lower quality GRP/plastic competitors.

There are no moving parts or pumps in the plant which is ensuring reliable operation during the treatment process and minimal running costs.

Tricel Novo plants are designed with a shallow invert to limit both installation and time costs.

Product availability and lead time

We supply both commercial sewage treatment plants and small domestic sewage treatment plants. As a manufacturer, we ensure the best-sellers are available in stock. Larger size plants can be manufactured to meet the customer’s timeline.

As a reference, the average lead time for 6-12 population Novo systems is 3 to 5 working days.

Once an order is placed and the delivery date is agreed upon, we will ensure the timeline is respected. We understand how disruptive late deliveries can be to a project.

We also work closely with our network of installers and builders merchants to ensure they can fulfil their orders. Deliveries directly to the site are also an option in case of short lead time or lack of storage space.

At Tricel, we also provide on-site support thanks to dedicated Area Sales Managers.

articles you may be interested in

- Maintenance

- Regulations

- Wastewater Treatment

MEET OUR TEAM

To find a technician in your area, visit our page

TALK SEWAGE TREATMENT

To speak to one of our agents online, click here

ASK FOR A QUOTE

Request a free quote today to have a quote that meets your project!

Key Features

Fast Delivery

Fast delivery + Rapid response to all our customers

Certified

Tricel Products are certified to EN12566-1 and EN 12566-3 certified

Technical expertise

Unrivalled technical expertise by our sales team regarding wastewater treatment solutions

Get in touch