SEWAGE TREATMENT

How to clean septic tank and How to Remove Sewage Sludge

OVERVIEW

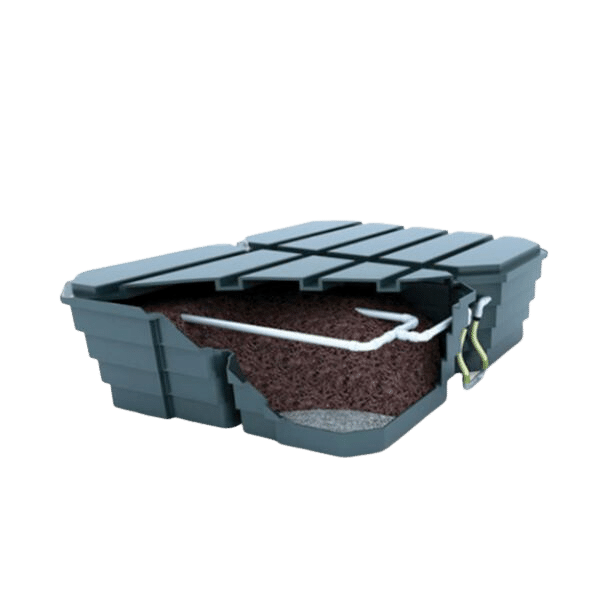

Knowing how clean a septic tank and how to remove septic tank sludge from your domestic wastewater treatment system (septic tank or sewage treatment plant) is necessary for multiple reasons. Importantly, carrying out this action ensures the protection of your soakaway system. It also respects the environment while protecting the quality of the treated wastewater. Lastly, it ensures your tank operates correctly and without the risk of failure.

Every septic tank or sewage treatment plant requires regular emptying as part of their maintenance.

De-sludging is necessary at least once a year to prevent system failure as solids could rise to the height of the outlet pipe and then get carried along with the liquid into the percolation area. The trenches could then be blocked and cause flooding.

How often should sewage sludge be removed?

Depending on usage and the number of house occupants, your de-sludging may be more frequent.

You will need to often monitor the level of the sludge.

How to remove sewage sludge?

This process carries out with a vacuum tanker by a professional. You cannot do this task by yourself under any circumstances:

- Remove the access cover

- Empty the sewage treatment plant or septic tank using a vacuum tanker. Care must be taken not to damage the unit with the hose of the vacuum tanker.

- Replace the de-sludging access cover securely.

Important notes:

- Do not let this heavy equipment drive over the tank. Maintain a distance of at least four meters away from the covers of the tank.

- The access cover should never be left off while the unit is unattended.

- Never undertake de-sludging alone.

- The property owner has a legal responsibility to ensure that all necessary precautions are taken to prevent pollution, a health hazard or nuisance.

Who can remove sewage sludge?

The de-sludging of your sewage treatment system is your responsibility as the homeowner. It is required when the sludge, that comes from the first sewage treatment inside the tank, occupies 50% of the volume of the primary chamber.

A a licensed waste disposal company must empty the tank for health and safety reasons. Indeed, sewage can carry bacteria and gases harmful to human health. That’s why only qualified people should carry out this type of maintenance.

Moreover, suitable protection equipment including gloves, goggles, etc. should be worn at all times and removed after completion of work.

It is also essential to wash hands and face before eating, drinking, or smoking afterwards.

You can check out on the Environment Agency website the register of waste carriers, brokers, and dealers to find a competent company.

Regular maintenance checks

- Check the sludge level – visual inspection. If the tank is more than half full, it might be time to book a de-sludging service.

- Check outlet distribution box when available (the effluent should be free-flowing and clear).

- Check all vents (not blocked or covered with overgrown grass).

- Check air blower (when available); you should hear a gentle sound.

- Check for odours.

MEET OUR TEAM

To find a technician in your area, visit our page

TALK SEWAGE TREATMENT

To speak to one of our agents online, click here

ASK FOR A QUOTE

Request a free quote today to have a quote that meets your project!

key features

quality

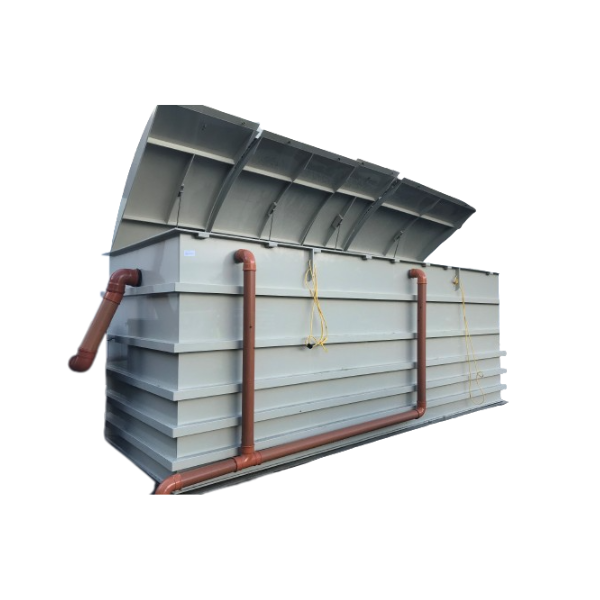

Sewage treatment plants are extremely reliable and durable as they are made out of long-lasting materials (20 to 40 years)

Fast delivery

UK manufactured ensuring short lead time

Certified

Our products are certified to EN12566-1 and EN12566-3

Get in touch