Nutrient neutrality is now vital for new developments: reducing contributions of nitrogen and phosphorus through advanced wastewater treatment (like Tricel’s PhosClear) helps protect rivers, lakes, and comply with planning regulations.

If you have any questions, feel free to call us

What is Nutrient Neutrality?

Nutrient neutrality is an environmental planning principle increasingly adopted by regulators to ensure that new developments do not increase the load of nutrients – particularly phosphorus and nitrogen – entering sensitive water bodies. When areas are already under pressure from nutrient pollution, planning authorities may require that any new discharge be offset or mitigated, to maintain or restore water quality.

Why Nutrient Neutrality Matters

Protecting ecosystems

Excess nutrients in rivers and lakes lead to eutrophication – algal blooms, loss of oxygen, fish kills, poor biodiversity. Limiting phosphorus discharge helps avoid these outcomes.

Legal/regulatory compliance:

In many parts of the UK, Local Planning Authorities (LPAs) require nutrient neutrality assessments for developments, often following guidance from environmental agencies such as Natural England.

Long-term sustainability

Clean water supports human health, recreation, wildlife, and reduces downstream treatment costs. Moreover, laws like the Environment Act 2021 set targets (e.g. large reductions in phosphorus discharge by 2038) that make compliance essential.

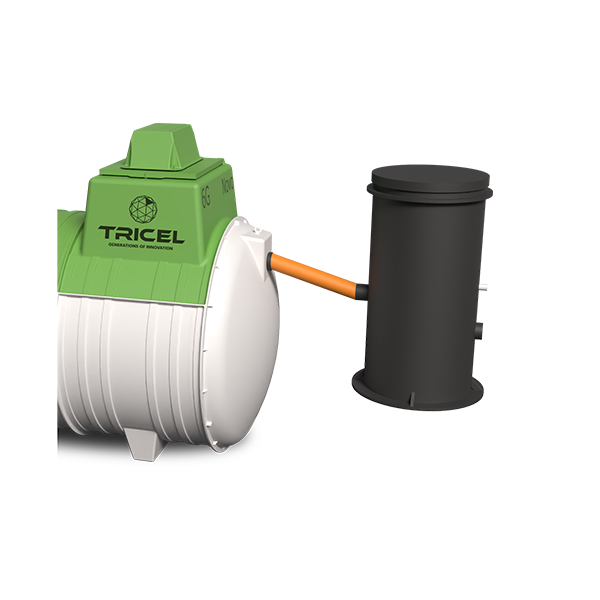

The Tricel PhosClear is our solution for phosphorus removal in wastewater. It is designed to effectively reduce phosphate levels, ensuring compliance with environmental regulations and helping protect water quality. Whether you’re managing a domestic treatment system or a larger-scale installation, our product offers a reliable and efficient way to minimise phosphate pollution.

Phosphorus Removal: The Technical Backbone

To achieve nutrient neutrality, reducing phosphorus in wastewater is essential. Here’s how advanced treatment systems can help:

Phosphate vs phosphorus: Phosphorus from wastewater usually ends up as phosphate, which causes the disruptive effects in water systems.

Sources: Human waste, detergents, agricultural runoff. All contribute to the phosphorus load that must be controlled.

Technological solutions:

Tricel’s PhosClear is a plug & play, ready‐to‐install system that reduces phosphorus (and E.coli) without chemical dosing. It can deliver treatment levels as low as 0.8 mg/L phosphorus, removes up to 95% of phosphorus, and helps in meeting sensitive discharge standards.

The system uses natural media (Polonite) in chambers through which treated effluent passes in alternating flow, adsorbing phosphorus and disinfecting residual E.coli.

Nutrient Neutrality & Planning: What Developers Need to Know

Developers must show that proposed projects will not add to nutrient pollution in catchments already over critical loads. Key steps:

Assessment – Determine whether the site lies in a “nutrient neutrality catchment.” If it does, then the development’s nutrient load must be calculated.

Mitigation or offsetting – Either reduce discharges (via enhanced treatment, best management practices, changing landscaping, limiting fertiliser use, etc.) or contribute to off-site mitigation. Phosphorus removal systems are a strong tool here.

Compliance – Treat wastewater so that phosphate or phosphorus discharge meets relevant limits; maintain systems properly; document performance.

How Phosphorus Removal Supports Nutrient Neutrality

By integrating treatment units like PhosClear:

New development proposals can show significantly reduced phosphorus loads, helping satisfy nutrient neutrality requirements from LPAs.

Systems with high removal efficiency (up to ~95%) mean much less risk of exceeding discharge thresholds.

Low maintenance, no‐chemicals solutions reduce operational burdens and environmental risks.

Plug & Play

Eco‑Friendly

UK‑Tailored Design

Challenges & Considerations

Cost and installation logistics: Upfront cost of treatment units, ensuring proper installation, space, power, etc.

Maintenance: Even low-maintenance systems need periodic checkups, swapping the media bags, ensuring flows are correct.

Monitoring and verification: Need data to demonstrate that treated effluent meets agreed phosphorus levels.

Conclusion

If you are planning a development, nutrient neutrality can’t be ignored. Phosphorus removal technologies like Tricel’s PhosClear offer proven performance to reduce nutrient loads, protect sensitive water bodies, and comply with increasingly strict environmental regulations. Investing in good treatment now means avoiding regulatory risk, environmental harm, and potential planning refusals.

articles you may be interested in

Tricel product range

Tricel Novo Sewage Treatment Plant

Durable & long lasting SMC tank, shallow dig tank, easy installation (Plug and Play), long life components.

Tricel Phosphorus Removal

Tricel PhosClear is a ready-to-install system that reduces Phosphorus wastewater without using chemicals.

Tricel Maxus Sewage Treatment Plant

Commercial plant. Submerged Aerated Filter (SAF) technology. Ideal for every project over 50 Population Equivalent.

Tricel Vento

Septic Tank

Shallow dig tank, strong & robust underground tank, no electrical or moving parts.

Tricel Tero Tertiary System

Next Generation tertiary wastewater treatment unit with proven E.Coli treatment capabilities.

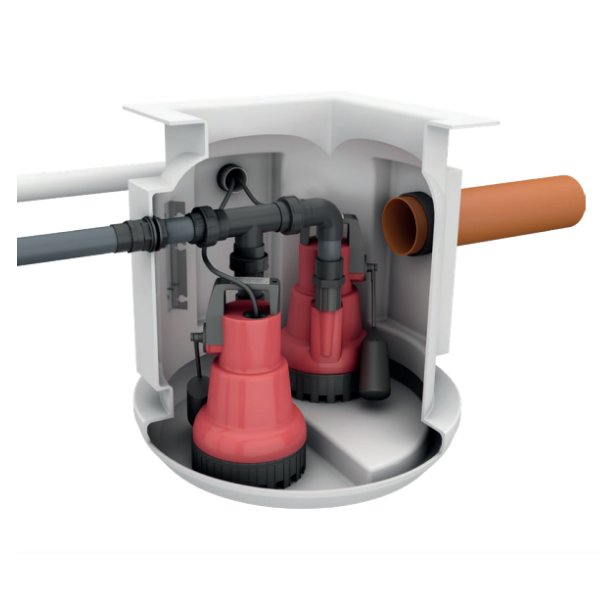

Tricel Pumping

Stations

Pump fluids from one place to another where gravity drainage cannot be used, easy and trouble-free installation.

50 YEARS IN BUSINESS

A highly successful multinational corporation with over 50 years’ valuable industry experience

SEWAGE TREATMENT PLANTS

Plants available for all capacities, from 1PE up to 50PE. Free advice on request.

FAST DELIVERY

On-time delivery is a core requirement of our successful business operations

Get in touch