SEWAGE TREATMENT

Packaged Filter Systems - Tricel Puraflo

OVERVIEW

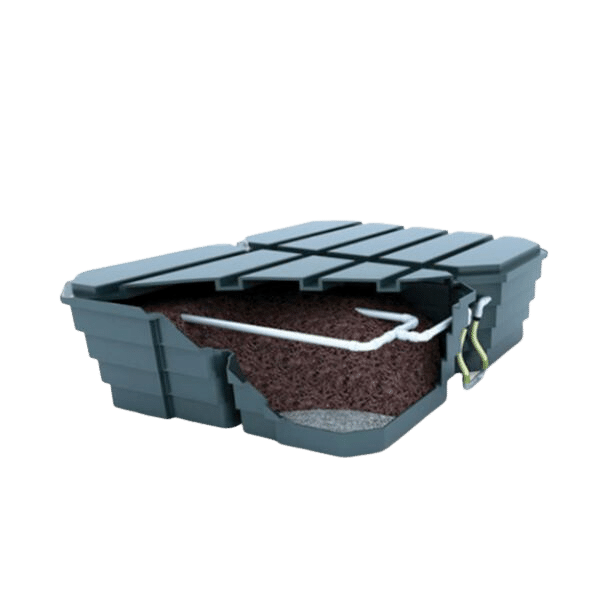

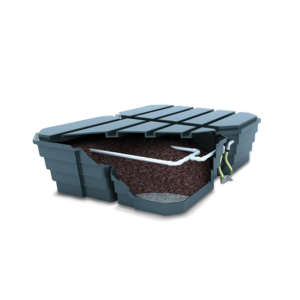

Tricel Puraflo is an eco-friendly, modular secondary (after a septic tank) or tertiary treatment system (after a wastewater treatment plant). The system uses a bio-fibrous coconut fibre filter system making it one of the most sustainable wastewater treatment systems available with very little energy consumption.

Tricel Puraflo works with your existing Septic Tank or Tricel Novo sewage treatment plant, where a higher level of effluent filtration is required before being dispersed into the ground.

Secondary & tertiary sewage treatment is the final cleaning process. It improves wastewater quality before reusing, recycling, or discharging to the environment. Our packaged filter system, Puraflo, may be submitted as part of a tertiary treatment application.

PACKAGED FILTER SYSTEMS KEY BENEFITS:

• ISO 9001 accredited

• Certified to European Standard EN12566-3

• A 100% natural system: remarkable filtration properties of coconut fibre and uses no chemical additives in achieving exceptional results

• Low carbon footprint

• Highly effective tertiary treatment when installed after a sewage treatment plant

• Up to 99.9% reduction in total coliforms

• Up to 99.9% elimination of the pathogenic bacteria

• Odour absorption properties: suppressing sewage odours

• Minimal power requirements, costs typically averaging approximately £10 per annum

• Really quick and simple installation: can be installed above or at ground level

• It require no de-sludging or backwashing

• Suited for either main or holiday residence applications: Intermittent or seasonal flows have no detrimental effect on treatment levels

• One only mechanical device in the system: the pump, which works on an intermittent basis, minimising the possibility of mechanical problems

If you have any questions, feel free to call us or use our quote form

To speak to one of our agents online, click here

To find a technician in your area, visit our page

What is a packaged filter system?

Packaged filter systems are required for environmentally sensitive sites; sites in watershed protection areas often require enhanced treatment. Combining a tertiary sewage treatment plant with a secondary treatment system, typically an aerobic treatment unit, achieves this requirement.

The Tricel Puraflo system connects to your existing septic tank/sewage treatment plant. The secondary treated effluent is dosed to Puraflo polishing filter modules and undergoes a third stage or tertiary treatment. The combined system will provide a very high pathogen and nutrient reduction level.

The treatment removes remaining inorganic compounds and substances, such as nitrogen and phosphorus. Packaged filter systems are required for environmentally sensitive sites such as sites in watershed protection areas.

How do Tricel Puraflo packaged filter systems work?

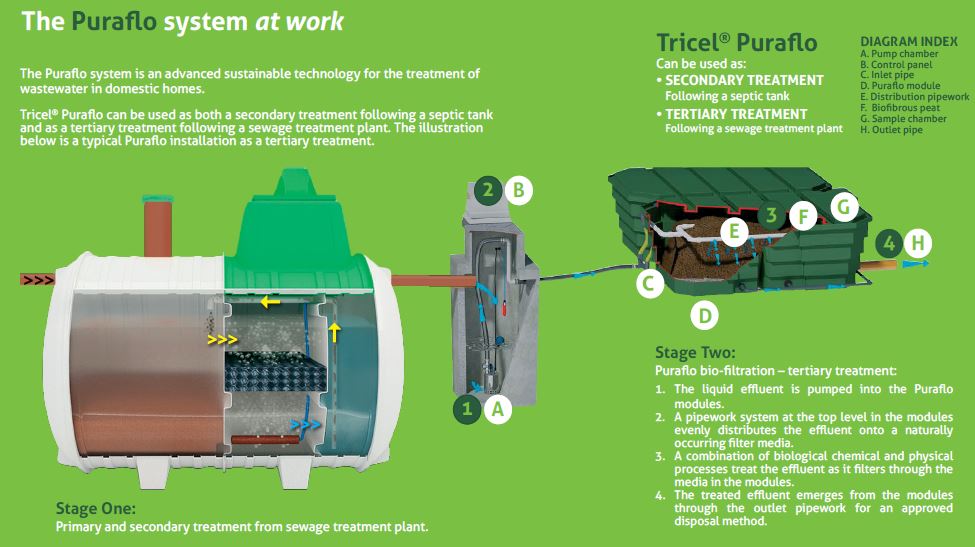

This illustration below is a typical Puraflo installation as a tertiary treatment.

Stage one: Primary and Secondary treatment from a sewage treatment plant

Stage two: Puraflo Biofiltration – Tertiary treatment

- The liquid effluent is pumped to the Puraflo modules.

- A pipework system at the top level in the modules evenly distributes the effluent onto a naturally occurring filter media.

- A combination of biological, chemical and physical processes treat the effluent as it filters through the media in the modules.

- The treated effluent emerges from the modules through the outlet pipework for an approved disposal method.

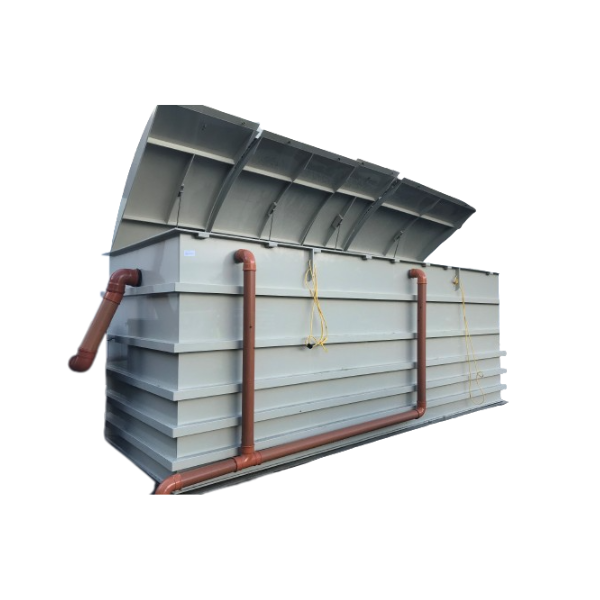

Puraflo Commercial Sizing

This table indicates typical system sizes for sample population equivalents.

|

Population Equivalent (PE)

|

Maximum Daily Flow (m3/d)

|

Applied Organic Load (kg/day BOD)

|

Number of Modules

|

|---|---|---|---|

|

20

|

3.6

|

1.2

|

8

|

|

50

|

9

|

3

|

18

|

|

80

|

14.4

|

4.8

|

28

|

|

100

|

18

|

6

|

36

|

|

150

|

27

|

9

|

54

|

Puraflo Commercial Module Specifications

|

Type

|

Specifications

|

|---|---|

|

Length

|

2150mm

|

|

Depth

|

760mm

|

|

Width

|

1400mm

|

|

Weight (one Puraflo module)

|

250kg

|

Certifications

Tricel wastewater treatment plants are fully tested and accredited to European standards for CE certification. The products meets with EN12566-3 requirements which test both the quality of the components as well as the overall performance of the platnt.

IF YOU NEED MORE INFORMATION

Call us now to talk about your project and we will answer your questions or concerns.

ASK FOR A QUOTE

Request a free quote today to have a quote that meets your project!

Interact with the Tricel PURAFLO PACKAGED FILTER SYSTEM

- Click on the numbers to see the annotations.

- To view in Virtual Reality (VR), click the square at the top right-hand corner and simply scan the QR code with your phone.

- In order to check the dimensions, click on the spanner icon.

- To download an image of the Puraflo module, click on the camera icon (top right-hand corner)

key features

Cost effective solution

Minimal maintenance is required with our Tricel Puraflo systems: fewer de-sludging operations and reduced operational costs.

Easy installation

Puraflo units do not require concrete backfill and can utilise the existing excavated material as backfill. Therefore, the installation is quick and simple.

Low Carbon Footprint

Our packaged filter system is a 100% natural system that draws on the remarkable filtration properties of peat and uses no chemical additives in achieving exceptional results.

Recent Projects

Extensive industry experience, manufacturing since 1973.

Tricel manufacture deliver & install sewage treatment plants across a wide range of industry sectors throughout Ireland & the UK. Tricel also provide import/export services for our international clients. Top quality material offers outstanding capabilities including long life, durability and is a cost-effective solution for sewage treatment even in the harshest environments.

Tricel has installed many of its Tricel Puraflo Packaged Filter Systems accross the UK.

Check some of our projects by clicking on the button below.

50 YEARS IN BUSINESS

A highly successful multinational corporation with over 50 years’ valuable industry experience

SEWAGE TREATMENT PLANTS

Plants available for all capacities, from 1PE up to 50PE. Free advice on request.

FAST DELIVERY

On-time delivery is a core requirement of our successful business operations

Frequently Asked Questions

Domestic wastewater is all wastewater generated inside the house, including grey water from sinks, showers, baths and sewage from toilets. Rainwater is not classified as greywater and should be directed to a soakaway. CONTACT US

A wastewater treatment plant treats the wastewater better, typically 20 times cleaner than a septic tank. Find out how a septic tank works and how a sewage treatment plant works.

Once the water is discharged, it must either go to a drainage field of slotted brown sewer pipe or into a running watercourse. If released directly into the ground, it would fail and block up in a concise space of time. Also, it would contradict the government’s General Binding Rules for small sewage discharges—more information on this page.

Get in touch