SEWAGE TREATMENT

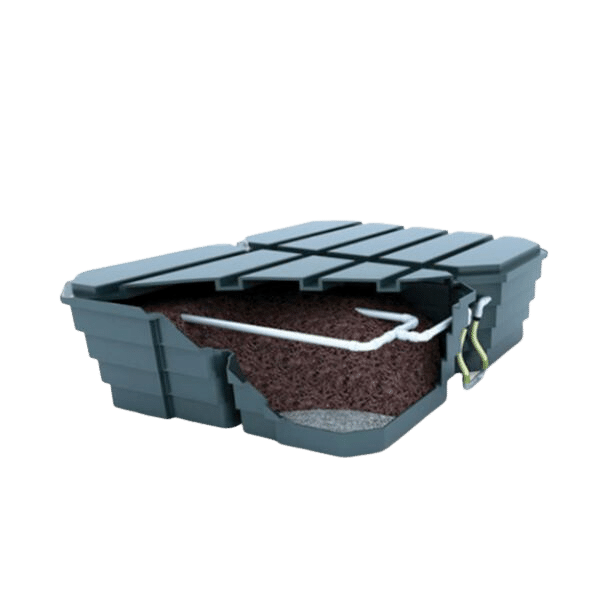

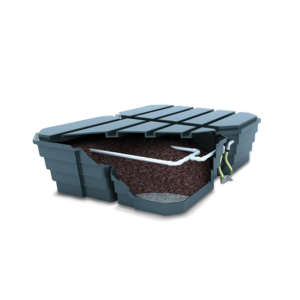

Package Treatment Plant: Tricel Novo

OVERVIEW

Definition of a Sewage Treatment plant

We intend a sewage treatment plant primarily for individual homes and businesses (package treatment plant) that cannot connect themselves to a main sewer. It works on the same principle as the collective purification plants but in a miniaturised version for individual use.

The owners of wastewater treatment plants must follow the “Small Sewage Discharges in England: General Binding Rules” issued by the Department of the Environment, Food and Rural Affairs. Different rules apply for sewage treatment systems in Northern Ireland, Scotland and Wales.

KEY BENEFITS OF A TRICEL NOVO PLANT:

- Compact: about five m² of floor space (for five or six population equivalents);

- Lightweight: (200 to 300 kg): easy and inexpensive installation (sewage treatment plant with concrete tank weights more than two tons);

- Efficient: effective treatment, no risk of clogging;

- Adaptable: suitable for all types of terrain (difficult ground, the presence of groundwater);

- Reliable: long life (20 to 40 years, whereas the spreading of a traditional die must be replaced every 10 to 20 years);

- Tested and certified: for structural strength, water tightness, durability and treatment efficiency, adhering to European Standard EN12566- 3 (like all sewage treatment solutions that Tricel manufactures)

Table of Contents

If you have any questions, feel free to call us

VISIT OUR VIRTUAL SHOWROOM

The diverse types of Package treatment plant

The Package treatment plant contains two large families:

With a free bacterial culture

With a culture fixed on a support

1. Free cultures

Two technologies are available.

On the one hand, there is the “classic” activated sludge sewage treatment plant, and on the other, a more technically version, the SBR.

Activated sludge:

It is the most common solution in package treatment. Generally, this technology is based on a tank with two compartments only, one for aeration and treatment and the other for settling and clarification.

It is the least efficient of the solutions if we compare it to the two other technologies below because it generates more sludge and does not support the variations of loads.

SBR (Sequencing Batch Reactor):

We suspend the sludge in the sewage treatment plant, usually in a single tank. We will treat the effluents thanks to a complex electronic system which activates the distinct phases of treatment intermittently to allow the oxygenation of the effluents:

Stage 1: The decantation: the separation of the sludge and heavy solids from the effluents.

The Stage 2: The clarification: the effluents are clearer thanks to the deposition of residual pollution at the bottom of the tank.

Stage 3: The evacuation: We now discharge the clean wastewater to surface water.

2. Fixed bed:

Sewage treatment plants with fixed bed do generally not include electronics. A compressor sends air into the treatment compartment, which a diffuser transforms into micro-bubbles to oxygenate the effluents. Bacteria that attach and grow on the bacterial bed use this oxygen to degrade the pollution in the effluents.

How is a Tricel Novo plant working?

The operation of wastewater treatment, more commonly known as a sewage treatment plant, is a biological process. Microorganisms, naturally present in the wastewater of the house, will feed on the organic pollution they contain and thus degrade it by developing. To do this, some of these bacteria need oxygen.

The wastewater treatment process is broken down into stages:

1. The primary settling:

During this phase, the sludge and the heaviest solids are deposited at the bottom. The effluents are thus rid of most of their pollution before proceeding to the second phase of the treatment. This step is only sometimes taken up in free crop operations. For SBR stations, we alter it that combine the first and second stages.

2. Aeration:

This phase makes it possible to feed the bacteria with oxygen. The means vary from one type of sewage treatment plant to another. As a rule, airing is done using the air supply of a compressor and a diffuser. The bacteria thus have the oxygen molecules necessary for the biological degradation of the pollution.

3. Final settling and clarification:

During this stage, residual sludge, denser than water, will settle at the bottom of the tank. This process allows a final separation between water and residual pollution. We treat the water and it is then compliant with the standards of rejection in force. You can then release it from the tank to the natural environment.

Interact with the Tricel Novo Package Treatment Plant

How to interact with the tank

- Click on the numbers to see the annotations.

- You can also switch between the treatment process stages (yellow circle at the bottom left-hand corner) and the anatomy of the Novo (green circle at the bottom left-hand corner).

- In order to view in Virtual Reality (VR), click the square at the top right-hand corner and simply scan the QR code with your phone.

- To check the dimensions, click on the spanner icon.

- To download an image of the Novo, click on the camera icon (top right-hand corner)

Installation Exemples

Tricel Novo UK30 being installed

Tricel Novo installation result. Package treatment plant install.

Package treatment plant TRicel Puraflo installed in Scotland

Quality

WHY CHOOSE US

Because Tricel manufactures and chooses the best materials for the design of its products. Most Tricel products have warranties of up to 10 years guarantee. All our products within this product range is CE certified to EU safety, health and environmental requirements.

Please find below the list of our products and the warranty that is applied. Note that this warranty is only valid if the sewage system is properly installed by a qualified installer. Please also know that all warranties are subject to correct use of the product, including maintenance as per manufacturer guidelines.

Tricel Vento Septic Tank

Shallow dig tank, strong & robust underground tank, No electrical or moving parts. Ideal for sites with good drainage & plenty of space.

Tricel Novo Sewage Treatment Plant

Durable & long lasting SMC tank, shallow dig tank, easy installation (Plug and Play), long life components.

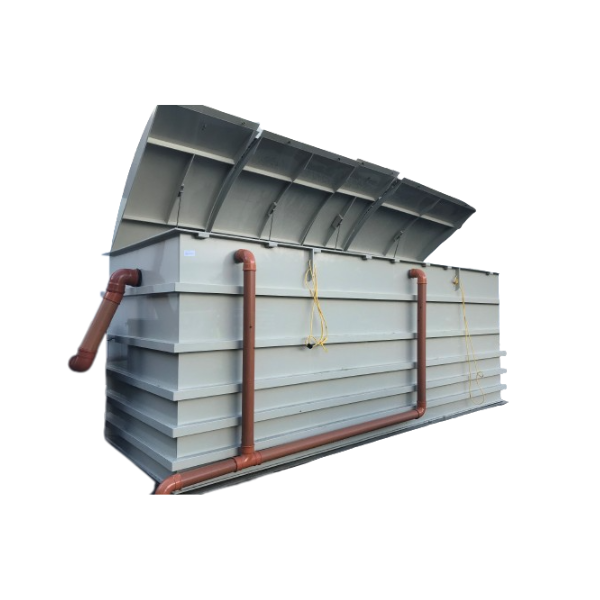

Tricel Maxus Sewage treatment Plant

Commercial plant. Submerged Aerated Filter (SAF) technology. Ideal for every project over 50 Population Equivalent.

Tricel Puraflo Packaged filter

Ideal for sensitive sites, compliant to British Standard, small footprint.

Tricel Pumping Stations

Pump fluids from one place to another where gravity drainage cannot be used, easy and trouble-free installation

50 YEARS IN BUSINESS

A highly successful multinational corporation with over 50 years’ valuable industry experience

SEWAGE TREATMENT PLANTS

Plants available for all capacities, from 1PE up to 50PE. Free advice on request.

FAST DELIVERY

On-time delivery is a core requirement of our successful business operations

Recent projects with package treatment plant

Extensive industry experience, manufacturing since 1973.

Tricel manufacture deliver & install sewage treatment plants across a wide range of industry sectors throughout Ireland & the UK. Tricel also provide import/export services for our international clients. Our top quality material offers outstanding capabilities including long life, durability and is a cost-effective solution for sewage treatment even in the harshest environments.

Tricel has installed many of its Tricel Novo Sewage Treatment Plants across the UK.

Check some of our projects by clicking on the button below.

Frequently Asked Questions

WHAT IS THE DIFFERENCE BETWEEN A CESSPOOL, A SEWAGE TREATMENT PLANT AND A SEPTIC TANK?

A cesspool is a simple storage vessel with an inlet and no outlet. It’s a sealed storage vessel; all the water coming in stays within the tank. The advantage is it doesn’t need an outlet. The disadvantages are: there is no treatment, the tanks are huge, and it needs regular emptying. You must suck out everything which has gone in. Ideal for sites which have got very infrequent use (Sheppard huts, for example).

Septic tank

A septic tank has an inlet and an outlet; it’s a simple overflow system. See how a septic tank works here. The advantages of the septic tank are there is no mechanic and no electricity requirement for it to work. The disadvantages are you are discharging dirty water, and untreated sewage effluent, as a tiny breakdown has occurred in the tank. You can only release water to a drainage field for the water to go through the subsoil to treat the water.

Sewage treatment plants

A sewage or package treatment plant has an inlet and an outlet; the wastewater is treated inside the tank. Aeration is provided inside the tank for the aerobic bacteria to feed on the waste and remove it from the liquid. The advantages are the wastewater is treated and can be discharged to a watercourse.

Many package treatment plants are available on the market:

- Trickles filters

- Rotating Biological Contactors (RBC)

- Mobile media bio-reactors

- Activated Sludge systems

- Sequence Batch Reactor systems (SBR)

- Fixed Bed Systems (like the Tricel Novo)

ARE THERE ANY SEWAGE TREATMENT PLANT REGULATIONS TO BE AWARE OF?

UK sewage treatment plants must comply with EN 12566-3 2005 regulations.

You should also hire a professional to install your sewage treatment system. For any sewage treatment plants you intend to install, you should also check your local guidelines to determine if planning permission is required.

HOW DO SEWAGE TREATMENT PLANTS WORK?

A sewage treatment plant is where domestic wastewater and sewage are treated. The sewage treatment plants break down organic matter through the primary settlement and aeration chambers. Sewage treatment plants require little maintenance and have low running costs, and sewage effluent is discharged into drainage fields or watercourses.

WHAT IS THE QUALITY OF THE WASTEWATER PRODUCED?

For example, the required standards are 20:30:20 for BOD, SS, and NH4.

Tricel® has achieved an 11:16:9 result during independent testing.

HOW LONG DOES IT TAKE FOR THE PLANT TO BEGIN OPERATING?

In order for the biomass to reach its optimum purification, it may take up to 16 weeks.

IS THE TREATED WASTEWATER REUSABLE?

You may be able to discharge directly into a watercourse or to a percolation area depending on your region. Find out which option is best for you by contacting your local council.

WHAT SIZE SEWAGE PLANT DO I NEED?

The sewage treatment plant’s size depends on the effluent volume from your house. It is determined by the number of people using the system, which is calculated based on the number of bedrooms in your home. If you need further information, contact our team.

WILL I NEED TO EMPTY (DESLUGING) MY SEWAGE TREATMENT PLANT?

Occasionally, your sewage treatment plant will need to be emptied due to the accumulated sludge inside – usually once a year. The frequency of emptying your treatment plant depends on its size and usage. See our dedicated page about desludging septic tanks and wastewater treatment plants.

WHY DOES THE USE OF RISERS MATTER?

1) to prevent surface water from entering the tank and overloading the system as this can inhibit growth of the bacteria and could reduce the effluent quality.

2) to prevent water getting into blower housing which can harm the control panel and the air blower.

Learn more about Tricel Novo risers.

Get in touch