SEWAGE TREATMENT

Commercial Sewage Treatment Plant

OVERVIEW

Tricel Maxus commercial sewage treatment plants are strong and easy to install, with numerous possible configurations to suit any site. The Plug & Play system is ideal, you just needs to connect the inlet, outlet & power supply – job done!

This commercial sewage treatment plant is simple in operation and easy to maintain over the product’s lifespan.

Great for seasonal / fluctuating loads, they are simple with a flexible system. They can adjust automatically to fluctuating flows & loads, saving the owner money and efforts.

The Tricel Maxus, is a commercial plant that uses Submerged Aerated Filter (SAF) technology. All electrical components of the plant are connected through the E-III control panel.

Examples of usages include:

- Camp sites / glamping sites

- Garden centres

- Golf clubs

- Zoo’s / animal parks / sanctuaries

- Care homes

- Visitors centre

- Housing developments / estates

- Motorway services / road side restaurants

- Hotels

- Factories

- Supermarkets & retail units

- Small shopping centres / out of town shopping outlets to name a few.

These highly versatile systems are individually sized to suit every scenario over 50 Population Equivalent.

Tricel is dedicated to meeting your needs with accredited partners, installers, and service teams who can maintain your systems, ensuring they fit your site specifications, conform to EA effluent requirements, and come with precise CAD drawings to suit any space requirements.

If you have any questions, feel free to call us or use our quote form

To speak to one of our agents online, click here

To find a technician in your area, visit our page

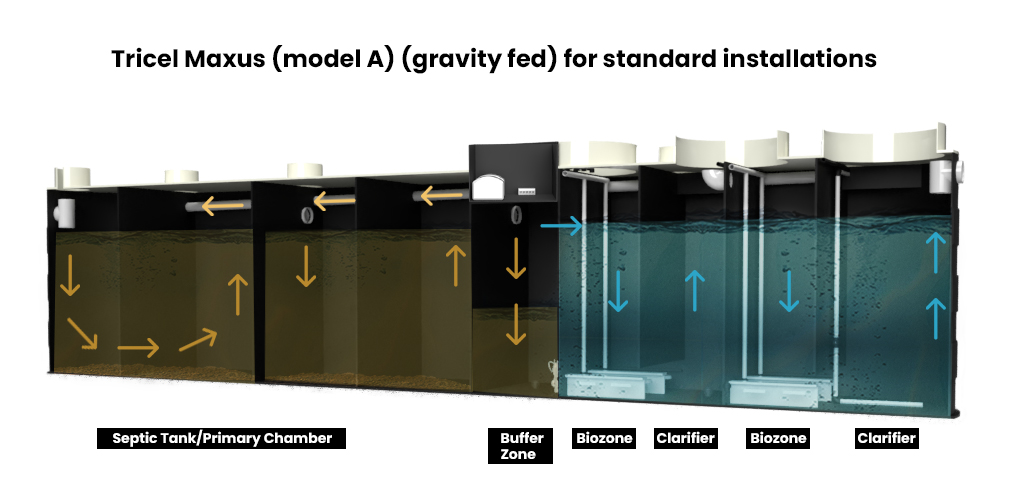

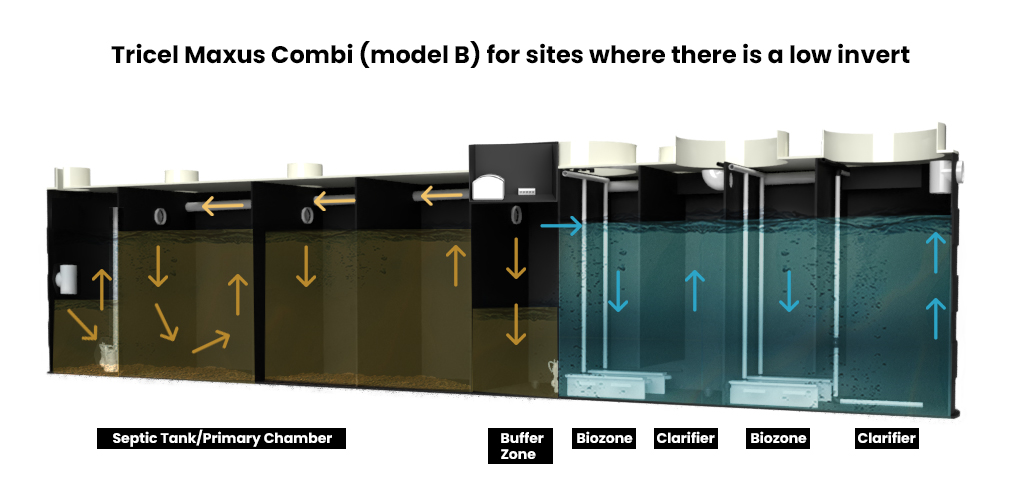

HOW DOES TRICEL MAXUS WORK?

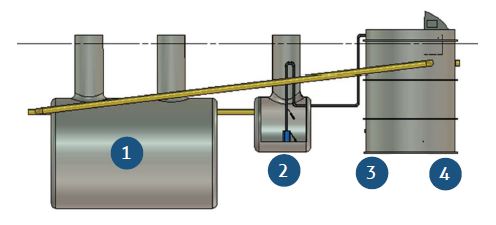

Tricel commercial sewage treatment plant range comprises of Tricel Maxus Combi (all in one tank) and the Tricel Maxus.

Both the Tricel Maxus and Maxus Combi commercial wastewater treatment systems use the same highly effective SAF technology. This technology treats wastewater through a four-stage process.

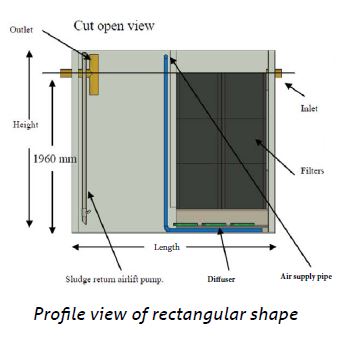

Stage 1: The settlement tank

The primary treatment occurs here. As the wastewater enters the Tricel Maxus system, the heavy solids are separated out and settle (forming a sludge on the tank’s base). Subsequently, the lighter solids, such as oils, fats or grease, float to the top of the wastewater and are retained within the settlement tank.

Stage 2: The buffer tank

The incoming water load fluctuations are evened out here. The wastewater is fed forward into the treatment plant thanks to pumps located at the bottom of the buffer tank.

Stage 3: The biological treatment zone

The wastewater passes through, the submerged aerated filter (with a large surface area for the microbes) and is exposed to aeration.

The aeration is matched to the incoming flow to ensure efficient operation, thanks to the adjustments made by the control panel. Because of this, the system will not clog nor need any maintenance or chemicals.

Stage 4: The clarifier

Here, the bio sludge from the treatment process settles out of the treated liquid. Thanks to the airlift pumps, the bio sludge from the tank’s base is recirculated back to the settlement tank. The fully treated liquid is now ready to discharge from the plant.

Key features & benefits

Pre-packaged and easy to install, our system is designed for quick, hassle-free setup.

Suitable for seasonal loads or constant loads. The control panel will automatically adjust to the incoming load to ensure optimum performance. This commercial plant can adapt to different loadings or effluent strengths.

Optimised for power savings, significantly reducing energy consumption and operational costs.

Proven SAF technology providing an excellent treatment. Simple, easy, tried & tested aeration system.

Low running costs (simple operation using long life reliable components).

Very low maintenance costs (especially when compared with RBC systems). No moving parts.

Full bespoke design engineered solutions offered to ensure best performance.

Suit any site (can fit into difficult sites or simply save space).

Extensively tested and ETA verified for holiday home applications. System will go into power saving mode during periods of no flow and restart once flow is detected without the need for any manual inputs.

Capable of producing minimal effluent, meeting stringent environmental standards.

Stay in control with remote access and monitoring, providing real-time insights and operational peace of mind.

Recent Projects with Tricel Maxus (commercial plant) Sewage Treatment

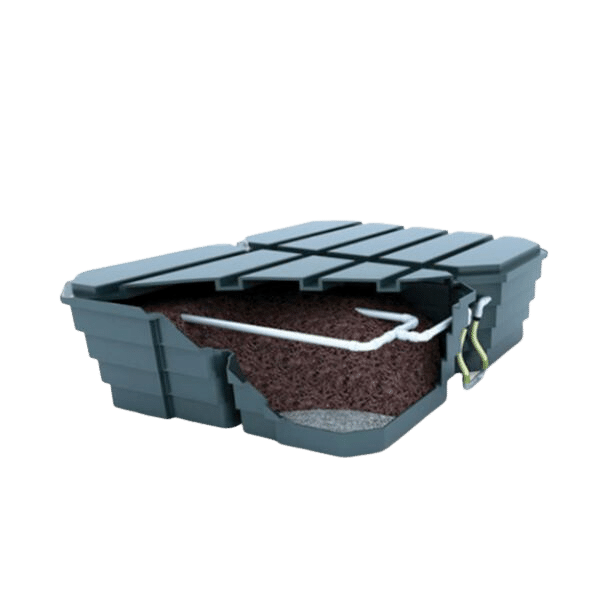

Tricel Maxus Combi (all in one tank) installations

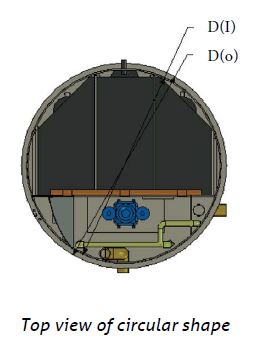

Tricel Maxus (circular shape) installations

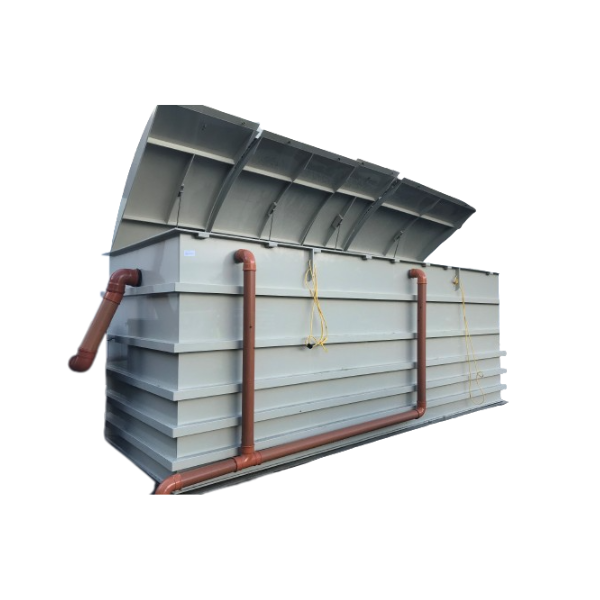

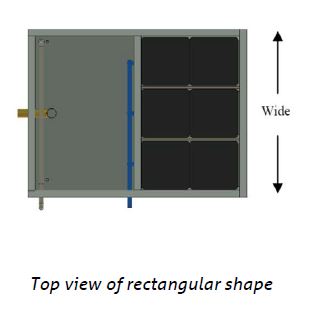

Tricel Maxus (rectangular shape) installations

Technical Characteristics Of Tricel's commercial plants

1. TRICEL MAXUS COMBI RANGE (ALL IN ONE TANK)

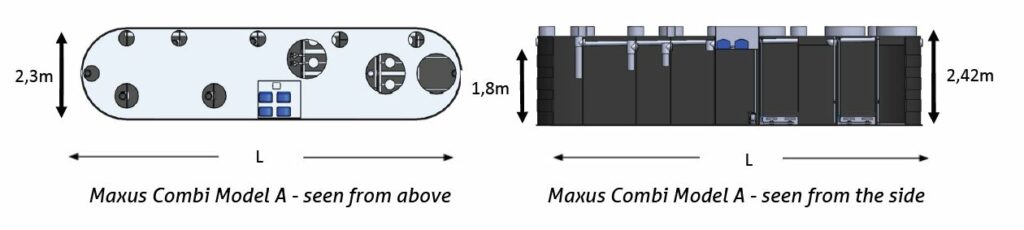

Dimensions for the Tricel Combi Model A, suitable for standard installations:

The invert level on Model A is 520mm, making it ideal for installations where the system is positioned low to the ground. This allows for either gravity flow into the system or water to be pumped into it.

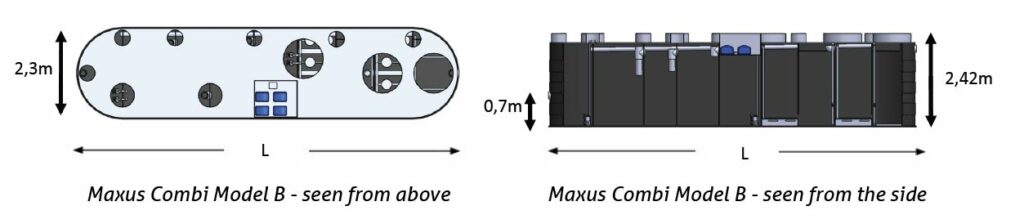

Dimensions for the Tricel Combi Model B, designed for sites with a low invert to avoid using risers and minimise the risk of surface water entering the tank:

The invert level on Model B is 1620mm, suitable for situations where water cannot flow by gravity to Model A but can flow by gravity to Model B without the need for pumping.

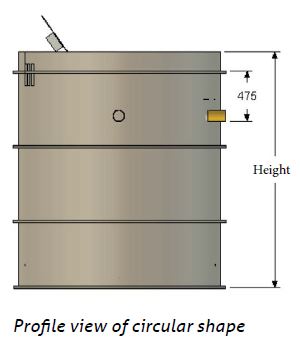

2. TRICEL MAXUS RANGE (MULTI TANKS)

Tricel Maxus (circular shape)

Tricel Maxus (rectangular shape)

Tricel Maxus (circular shape)

Tricel Maxus (rectangular shape)

Tricel Maxus (circular shape)

Tricel Maxus (rectangular shape)

TRICEL MAXUS SEWAGE TREATMENT PLANTS DIMENSIONS

The table below provides the dimensions of the Tricel Maxus Combi (all-in-one) treatment plants.

Tricel can recommend the optimal Maxus Combi solution for your project based on the population equivalent (PE) and the required treatment level.

| Combi 3A/B | Combi 4A/B | Combi 5A/B | Combi 6A/B | Combi 7A/B | Combi 8A/B | Combi 9A/B | |

|---|---|---|---|---|---|---|---|

| Height (m) | 2.42 | 2.42 | 2.42 | 2.42 | 2.42 | 2.42 | 2.42 |

| Width (m) | 2.30 | 2.30 | 2.30 | 2.30 | 2.30 | 2.30 | 2.30 |

| Length (m) | 5.782 | 6.975 | 8.497 | 10.212 | 11.126 | 12.209 | 12.9 |

| Weight (kg) | 1,650 | 1,950 | 2,550 | 3,250 | 3,650 | 4,300 | 4,750 |

| Weight w. water (kg) | 23,553 | 28,830 | 35,723 | 43,544 | 47,711 | 52,874 | 54,648 |

| Septic tank size (A/B) (m3) | 9.1/7.4 | 11.8/10.1 | 15.2/13.5 | 19.7/18.0 | 20.8/19.1 | 22.7/21.0 | 23.3/21.6 |

| Buffer tank size (m3) | 1.65 | 2.25 | 3 | 3.75 | 4.50 | 5.25 | 6 |

| Power consumption at max load (kWh/d) | 6.3 | 6.3 | 8.9 | 12.7 | 12.7 | 20.6 | 21.5 |

| Power consumption at min load (kWh/d)* | 1.9 | 1.9 | 2.7 | 3.8 | 3.8 | 6.2 | 6.5 |

| In-outlet pipe connection (mm) | 160/160 | 160/160 | 160/160 | 160/160 | 160/160 | 160/160 | 160/160 |

| Diaphragm Blower(s). Installed in the integrated tech box | 1 x 400lpm | 1 x 400lpm | 2 x 300lpm | 2 x 400lpm | 2 x 400lpm | 2 x 400lpm +2 x 240lpm | 2 x 400lpm +2 x 300lpm |

| Pumps in pump well | 2 x 550W grinder pump | 2 x 550W grinder pump | 2 x 550W grinder pump | 2 x 750W grinder pump | 2 x 750W grinder pump | 2 x 750W grinder pump | 2 x 750W grinder pump |

| Pumps in buffer tank | 2 x 370W sewage pump | 2 x 370W sewage pump | 2 x 370W sewage pump | 2 x 370W sewage pump | 2 x 370W sewage pump | 2 x 370W sewage pump | 2 x 370W sewage pump |

*Reduced energy consumption when loadings are lower.

The table below shows Tricel Maxus (multi-tanks) system sizes, but each system is designed to suit project requirements.

| Code | PE | Settlement And Buffer Tank* | Length (M) | Width (M) | Height (M) | Treatment Plant | Length (M) | Width (M) | Height (M) |

|---|---|---|---|---|---|---|---|---|---|

| Tank | Plant Shape** | ||||||||

| 66M5000 | 66 | Settlement | 6.60 | 1.64 | 2.05 | Circular | 2.00 | 2.00 | 2.20 |

| Buffer | 1.60 | 1.64 | 2.05 | ||||||

| 88M6000 | 88 | Settlement | 6.60 | 1.64 | 2.05 | Circular | 2.30 | 2.30 | 2.20 |

| Buffer | 3.60 | 1.64 | 2.05 | ||||||

| 112J25 | 112 | Settlement | 6.60 | 1.64 | 2.05 | Rectangular | 2.80 | 2.16 | 2.22 |

| Buffer | 6.60 | 1.64 | 2.05 | ||||||

| 154J50 | 154 | Combined | 5.70 | 2.87 | 2.70 | Rectangular | 3.30 | 2.16 | 2.22 |

| 175J75 | 175 | Combined | 6.17 | 2.87 | 2.70 | Rectangular | 3.95 | 2.16 | 2.22 |

| 238J100 | 238 | Combined | 9.05 | 2.87 | 2.70 | Rectangular | 5.45 | 2.16 | 2.22 |

| 294J50X2 | 294 | Combined | 10.89 | 2.87 | 2.70 | Rectangular | 6.60 | 2.16 | 2.22 |

| 285J75X2 | 385 | Combined | 14.12 | 2.87 | 2.70 | Rectangular | 7.90 | 2.16 | 2.22 |

| 560J100X2 | 560 | Settlement | 9.95 | 2.87 | 2.70 | Rectangular | 10.90 | 2.16 | 2.22 |

| Buffer | 9.95 | 2.87 | 2.70 |

*All settlement and buffer tank dimensions are for GRP tanks as standard. Concrete options are available.

** Please note, the treatment plant is circular for up to 88PE and rectangular for plants over 88PE.

REQUEST A QUOTE

Ask for a free quote today by clicking the link below

CONSULT THE BOCHURE

Learn more about the Tricel Maxus

key features

Proven SAF technology

Operates using Submerged Aerated Filter (SAF) technology.

Versatile technology

Can adapt to different loadings or effluent strengths.

Swift back up and service

Ensured by our dedicated UK team.

Tricel manufacture deliver & install sewage treatment plants across a wide range of industry sectors throughout Ireland & the UK. Tricel also provide import/export services for our international clients. This top quality material offers outstanding capabilities including long life, durability and is a cost-effective solution for sewage treatment even in the harshest environments.

Tricel has installed some of its Tricel Maxus Sewage Treatment Plants accross the UK.

Check some of our projects by cliching on the button below.

50 YEARS IN BUSINESS

A highly successful multinational corporation with over 50 years’ valuable industry experience

SEWAGE TREATMENT PLANTS

Plants available for all capacities, from 1PE up to 50PE. Free advice on request.

FAST DELIVERY

On-time delivery is a core requirement of our successful business operations

Frequently Asked Questions

Yes. We can adjust the set up of the system and add in dosing kits, filters etc to meet the needs of your site.

We can work with local environmental agencies to find a solution best for everyone. We can reduce effluent levels by adjusting the tank sizing and we can also add things like chemical dosing and UV treatment.

The system should be laid on a level load bearing surface made up of either compressed gravel or a concrete slab depending on the type of ground on site.

Our system can be back filled using compacted gravel on a dry site or if there is over 300mm ground water in the excavation then a semi dry concrete mix should be used.

Please never install a tank without first reading through our install manual as it could void the warranty. Paragraph 4.5 of our Tricel Combi manual covers this and all specification requirements needed to obtain the correct backfill material for your project.

Tricel work closely with a number of service and maintenance companies across the UK that we have put through completed training courses on our systems.

Each individual company would price a service and maintenance package based on the particulars of the project. More information in our Service & Maintenance manual.

Every 2-12 months depending on the size. Check our our service and maintenance manual.

Lead times are generally around 6-8 weeks. However, please let us know if you require something different and we’ll try our best to accommodate.

Yes, if you let us know at the start of the design we can size the buffer section of the tank larger so we can add on extra treatment zones in the future.

The Maxus Combi is delivered on a euro carrier vehicle and comes with straps attached to be lifted off.

On larger Maxus systems we would look at this as per project.

Get in touch