SEWAGE TREATMENT

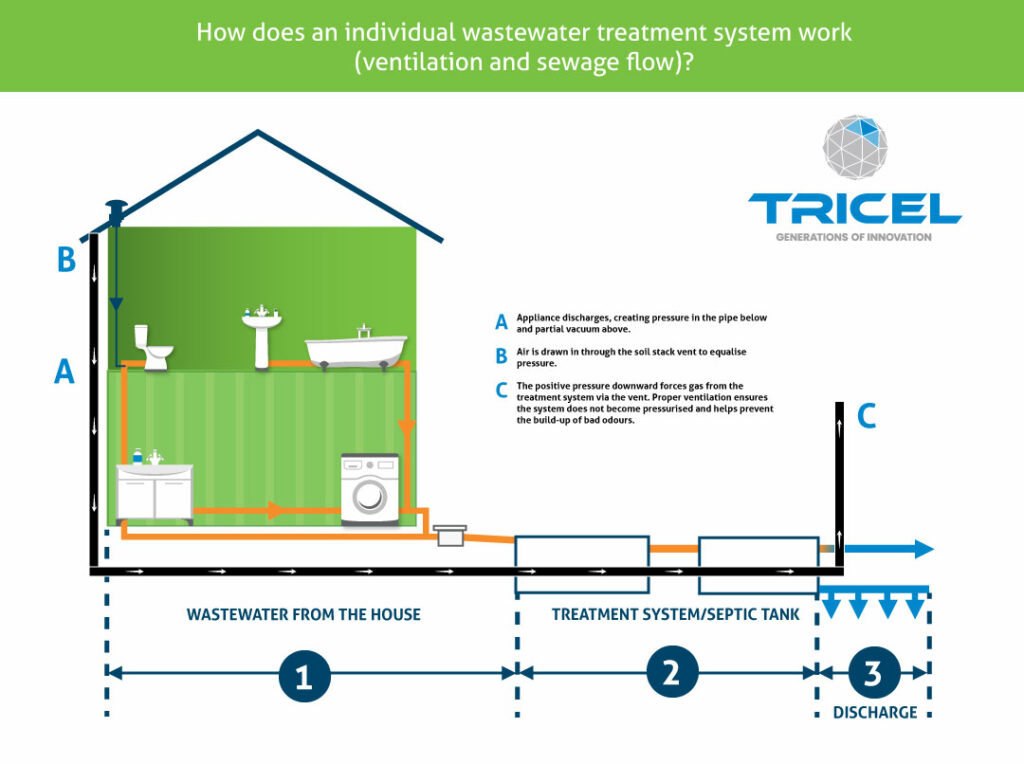

How does a sewage treatment plant work?

Home » Wastewater Treatment » How Does a Domestic Sewage Treatment Plant Work

Domestic sewage treatment plants are a relatively recent invention. They were created as sophisticated alternatives to septic tank systems. They are primarily used in parts of the UK where mains drainage is unavailable. Of course, since domestic sewage treatment plants are a relatively new technology, people need to become more familiar with them. Occasionally, someone will ask, “How does a domestic sewage treatment plant work?” Read on to learn all about the ins and outs of the functions of domestic sewage treatment plants!

KEY BENEFITS OF A TRICEL NOVO PLANT:

- Compact: about five m² of floor space (for five or six population equivalents);

- Lightweight: (200 to 300 kg): easy and inexpensive installation (sewage treatment plant with concrete tank weights more than two tons);

- Efficient: effective treatment, no risk of clogging;

- Adaptable: suitable for all types of terrain (difficult ground, the presence of groundwater);

- Reliable: long life (20 to 40 years, whereas the spreading of a traditional die must be replaced every 10 to 20 years);

- Tested and certified: for structural strength, water tightness, durability and treatment efficiency, adhering to European Standard EN12566- 3 (like all sewage treatment solutions manufactured by Tricel)

If you have any questions, feel free to call us

VISIT OUR VIRTUAL SHOWROOM

Early Sewage Treatment Processes

The process of treating domestic sewage consists of a series of filters. Each filter removes a certain kind of contaminant from the water. As a good rule of thumb, earlier treatments will remove larger contaminants, while later treatments will remove smaller contaminants.

The first filter in a domestic sewage treatment plant consists of a simple screen, and this first screen will have relatively large holes.

It is not designed to make the water any cleaner, instead, its purpose is to remove any large objects from the water.

These objects will generally consist of plant material like sticks or bunches of leaves. In some cases, they also include items like rags disposed of improperly.

It is important to remove these items so that the treatment plant remains free from the damage they can cause to more delicate processes later on.

The following two parts of early treatment at domestic sewage plants rely on gravity to clean water. They run water through a series of chambers.

In each chamber, the water flows for some time before moving on to the next chamber. The chambers have short walls that the water flows over.

The result is that the heaviest contaminants in the water sink to the bottom of the chambers. This allows the water to flow to the next chamber, free of those heavier contaminants.

The first couple of tanks like these remove contaminants like grit and sedimentation.

Later Domestic Sewage Plant Processes

Later stages in the treatment process address subtler contaminants. These include organic and chemical pollutants.

The water is run through a series of interlocking corrugated plastic sheets. There are particular bacteria on the sheets that eat up many organic contaminants.

Later on, the water will be mixed with chlorine to disinfect it. At the end of the process, the water will not yet be ready to drink or wash with, but it will be safe to return to the environment.

Learn How a Domestic Sewage Treatment Plant Works

Suppose you have ever wondered how a domestic sewage treatment plant works. In that case, this brief article on the subject has increased your understanding. Along with septic tanks, domestic sewage treatment plants are one of the best options for managing the waste products of an ordinary home. Regardless of which of these options you choose, it is important to find a quality provider.

To learn more about domestic security plans, septic tanks, and more, feel free to reach out to us

anytime here!

Stage 1: the primary settlement chamber

In the first sewage treatment stage, anaerobic breakdown occurs in the primary settlement chamber. The wastewater is introduced, and the solids drop to the bottom, becoming separated from the liquid.

Stage 2: the aeration chamber

The next stage of wastewater treatment involves aerobic breakdown. This occurs in the aeration chamber, where masses of naturally occurring bacteria inhabit specially designed filter media.

These bacteria are sustained with air, continuously supplied from a purpose-built pump in the unit’s top section. As the liquid flows slowly through the filter media, the bacteria feed on the waste and remove it from the liquid.

Stage 3: final settlement chamber

In the last stage of wastewater treatment, the liquid flows from the aeration chamber into the final settlement chamber. Suspended sludge consisting of bacteria is carried with the liquid into the settlement chamber. It settles to the bottom of the chamber.

From there, a continuous sludge return system pumps it back to the primary settlement chamber. The remaining treated liquid meets the required standard to pass out of the Tricel system safely.

Our promise for your domestic wastewater treatment plant

The compression moulding process is one of the most technologically advanced features available on the market. Components are manufactured under heat and high pressure. They have a competitive strength and durability over standard GRP tanks or PE tanks.

SMC is a unique material in the sewage treatment industry with Tricel SMC tanks operating in some of the harshest climatic conditions for over 50 years with no defects.

Tricel’s ceramic diffuser will last twice as long as all standard competitors rubber equivalents. It is a cost-saver in both call out fees and replacement parts.

No concrete backfill for installation on most sites which allows you to save up to €400 over lower quality GRP/plastic competitors.

There are no moving parts or pumps in the plant which is ensuring reliable operation during the treatment process and minimal running costs.

Tricel Novo plants are designed with a shallow invert to limit both installation and time costs.

Interact with the Tricel Novo Package Treatment Plant

How to interact with the tank

- Click on the numbers to see the annotations.

- You can also switch between the treatment process stages (yellow circle at the bottom left-hand corner) and the anatomy of the Novo (green circle at the bottom left-hand corner).

- To view in Virtual Reality (VR), click the square at the top right-hand corner and simply scan the QR code with your phone.

- In order to check the dimensions, click on the spanner icon.

- To download an image of the Novo, click on the camera icon (top right-hand corner)

Examples of installations (Tricel Novo sewage treatment plant)

articles you may be interested in

WHY CHOOSE US

Because Tricel manufactures and chooses the best materials for the design of its products. Most Tricel products have warranties of up to 10 years guarantee. All our products within this product range is CE certified to EU safety, health and environmental requirements.

Please find below the list of our products and the warranty that is applied. Note that this warranty is only valid if the sewage system is properly installed by a qualified installer. Please also know that all warranties are subject to correct use of the product, including maintenance as per manufacturer guidelines.

Tricel product range

Tricel Novo Sewage Treatment Plant

Durable & long lasting SMC tank, shallow dig tank, easy installation (Plug and Play), long life components.

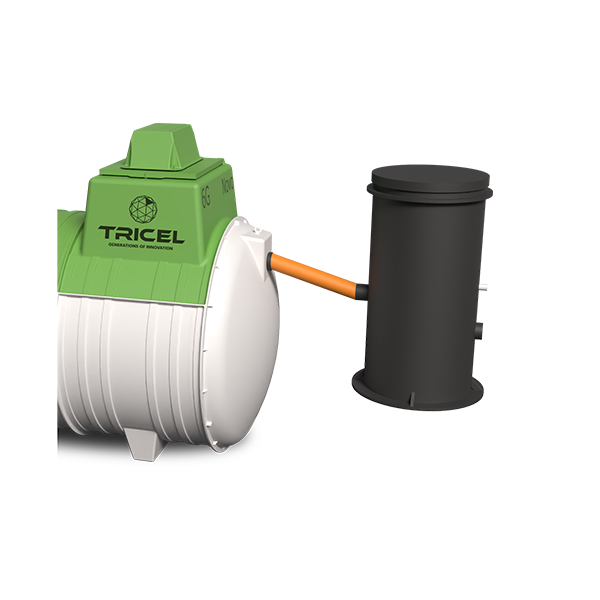

Tricel Phosphorus Removal

Tricel PhosClear is a ready-to-install system that reduces Phosphorus wastewater without using chemicals.

Tricel Maxus Sewage Treatment Plant

Commercial plant. Submerged Aerated Filter (SAF) technology. Ideal for every project over 50 Population Equivalent.

Tricel Vento

Septic Tank

Shallow dig tank, strong & robust underground tank, no electrical or moving parts.

Tricel Tero Tertiary System

Next Generation tertiary wastewater treatment unit with proven E.Coli treatment capabilities.

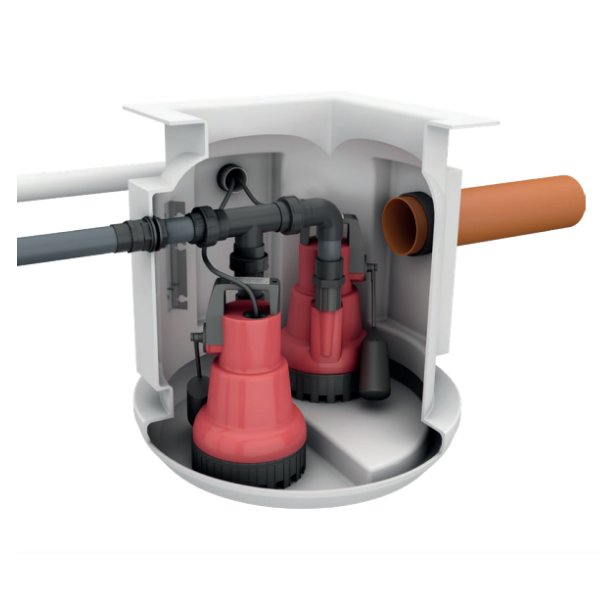

Tricel Pumping

Stations

Pump fluids from one place to another where gravity drainage cannot be used, easy and trouble-free installation.

50 YEARS IN BUSINESS

A highly successful multinational corporation with over 50 years’ valuable industry experience

SEWAGE TREATMENT PLANTS

Plants available for all capacities, from 1PE up to 50PE. Free advice on request.

FAST DELIVERY

On-time delivery is a core requirement of our successful business operations

Get in touch