SEWAGE TREATMENT

Tricel Treatment plant - Domestic & commercial purposes

Tricel offers high-performance solutions worldwide. Besides environmental products and its Tricel treatment plant, the company manufactures water tanks, meter boxes, and road safety products and distributes composite materials and lubricants. As a leading company in reinforced plastics, we have over 60 years of experience in press moulding and composites. Tricel is recognised as a standards-setter in the industry as a leading manufacturer of wastewater treatment plants in Europe.

Tricel manufactures the only European wastewater treatment plant from Sheet Moulding Compound (SMC). It has a higher strength-to-thickness ratio than any other tank on the market and does not rust over time.

Tricel offers two types of sewage treatment systems:

Both are highly reliable, easy to install and simple to maintain.

Discover more about both below, or contact us to discuss your requirements.

If you have any questions, feel free to call us

VISIT OUR VIRTUAL SHOWROOM

Tricel Treatment Plant: the Novo (projects up to 50 PE)

The Tricel Novo uses simple, proven fixed bed technology to suit domestic and light commercial or communal applications. Each wastewater treatment plant system comprises three independent treatment zones, all fulfilling three stages of the wastewater purification process.

This highly functional plant can serve populations ranging from 1 to 50 PE (Population Equivalent).

Our Tricel Novo products are made of one of SMC’s strongest glass-reinforced plastics available today. Thus, the product will have very high durability and robustness.

About five m² of floor space (for five or six population equivalents)

200 to 300 kg – easy and inexpensive installation (sewage treatment plant with concrete tank weights more than two tons)

Effective treatment, no risk of clogging

Suitable for all types of terrain (difficult ground, the presence of groundwater)

Long life (20 to 40 years, whereas the spreading of a traditional die must be replaced every 10 to 20 years)

For structural strength, water tightness, durability and treatment efficiency, adhering to European Standard EN12566- 3 (like all sewage treatment solutions manufactured by Tricel)

Tricel Treatment Plant: the Maxus (projects above 50PE)

A highly versatile system that can be customised to suit any situation over 50 Population Equivalents (PE). Examples of usages include factories, housing estates, nursing homes, caravan parks and campsites, schools, and hotels.

The Tricel Maxus sewage treatment plants use Submerged Aerated Filter (SAF) technology.

The systems are robust, easy to install, and can be configured in numerous ways to suit a variety of sites.

In addition to being simple in operation, they require little maintenance over the product’s lifecycle.

To ensure optimal performance, complete bespoke solutions are available.

Settlement tanks can be made of GRP or concrete.

The Control panel adjusts automatically to ensure optimum performance based on incoming load. It is capable of adapting to different effluent strengths and loadings.

The product was extensively tested, and the ETA was verified for holiday home applications. It will enter power-saving mode during periods of no flow and restart once the flow is detected without manual intervention.

Tricel product range

Tricel Novo Sewage Treatment Plant

Durable & long lasting SMC tank, shallow dig tank, easy installation (Plug and Play), long life components.

Tricel Phosphorus Removal

Tricel PhosClear is a ready-to-install system that reduces Phosphorus wastewater without using chemicals.

Tricel Maxus Sewage Treatment Plant

Commercial plant. Submerged Aerated Filter (SAF) technology. Ideal for every project over 50 Population Equivalent.

Tricel Vento

Septic Tank

Shallow dig tank, strong & robust underground tank, no electrical or moving parts.

Tricel Tero Tertiary System

Next Generation tertiary wastewater treatment unit with proven E.Coli treatment capabilities.

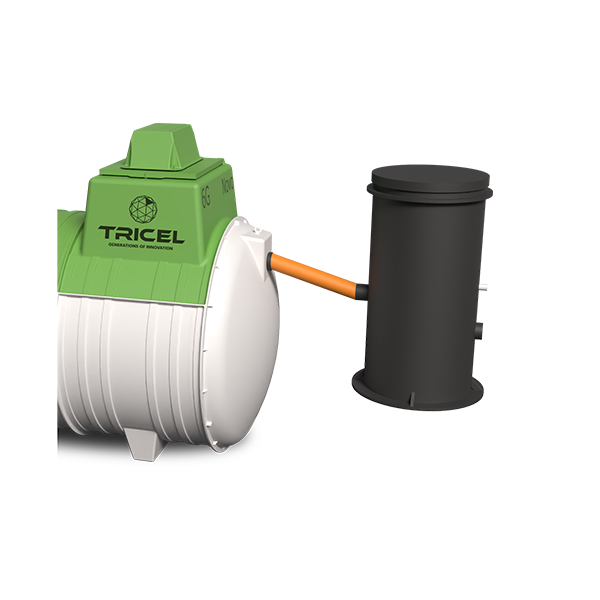

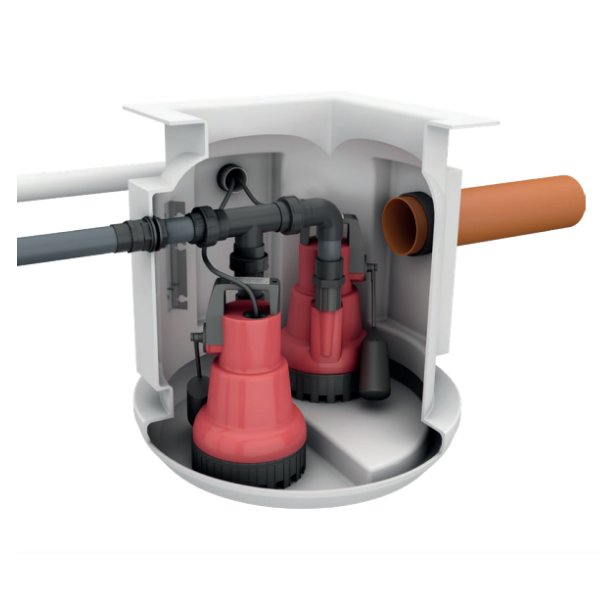

Tricel Pumping

Stations

Pump fluids from one place to another where gravity drainage cannot be used, easy and trouble-free installation.

Interact with the Tricel Treatment Plant

How to interact with the tank

- Click on the numbers to see the annotations.

- You can also switch between the treatment process stages (yellow circle at the bottom left-hand corner) and the anatomy of the Novo (green circle at the bottom left-hand corner).

- To view in Virtual Reality (VR), click the square at the top right-hand corner and simply scan the QR code with your phone.

- In order to check the dimensions, click on the spanner icon.

- To download an image of the Novo, click on the camera icon (top right-hand corner)

quality

WHY CHOOSE US

Because Tricel manufactures and chooses the best materials for the design of its products. Most Tricel products have warranties of up to 10 years guarantee. All our products within this product range is CE certified to EU safety, health and environmental requirements.

Please find below the list of our products and the warranty that is applied. Note that this warranty is only valid if the sewage system is properly installed by a qualified installer. Please also know that all warranties are subject to correct use of the product, including maintenance as per manufacturer guidelines.

50 YEARS IN BUSINESS

A highly successful multinational corporation with over 50 years’ valuable industry experience

SEWAGE TREATMENT PLANTS

Plants available for all capacities, from 1PE up to 50PE. Free advice on request.

FAST DELIVERY

On-time delivery is a core requirement of our successful business operations

Articles you might be interested in

Discover our projects

Tricel manufacture deliver & install sewage treatment plants across a wide range of industry sectors throughout Ireland & the UK. Tricel also provide import/export services for our international clients. Top quality material offers outstanding capabilities including long life, durability and is a cost-effective solution for sewage treatment even in the harshest environments.

Tricel has installed many of its Sewage Treatment Plants across the UK.

Check some of our projects by clicking on the button below.

Frequently Asked Questions

A cesspool is a simple storage vessel with an inlet and no outlet. It’s a sealed storage vessel; all the water coming in stays within the tank. The advantage is it doesn’t need an outlet. The disadvantages are: there is no treatment, the tanks are huge, and it needs regular emptying. Everything which has gone in must be sucked out. Ideal for sites which have got very infrequent use (Sheppard huts, for example).

A septic tank has an inlet and an outlet; it’s a simple overflow system. See how a septic tank works here. The advantages of the septic tank are there is no mechanic and no electricity requirement for it to work. The disadvantages are you are discharging dirty water, and untreated sewage effluent, as a tiny breakdown has occurred in the tank. You can only release water to a drainage field for the water to go through the subsoil to treat the water.

A sewage or package treatment plant has an inlet and an outlet; the wastewater is treated inside the tank. Aeration is provided inside the tank for the aerobic bacteria to feed on the waste and remove it from the liquid. The advantages are the wastewater is treated and can be discharged to a watercourse.

Many package treatment plants are available on the market:

- Trickles filters

- Rotating Biological Contactors (RBC)

- Mobile media bio-reactors

- Activated Sludge systems

- Sequence Batch Reactor systems (SBR)

- Fixed Bed Systems (like the Tricel Novo)

Domestic wastewater is all wastewater generated inside the house, including grey water from sinks, showers, baths and sewage from toilets. Rainwater is not classified as greywater and should be directed to a soakaway.

A trial hole can be dug during the site assessment and left open for 48 hours to determine this. The ground level is used to measure the water level.

After the water is discharged, it must flow into a drainage field or a running watercourse. It will fail and block up very quickly whenever it is released directly into the ground. It will also violate the government’s General Binding Rules for small sewage discharges—more information on this page.

MEET OUR TEAM

To find a technician in your area, visit our page

TALK SEWAGE TREATMENT

To speak to one of our agents online, click here

ASK FOR A QUOTE

Request a free quote today to have a quote that meets your project!

Get in touch