SEWAGE TREATMENT

Foul Water Pump stations

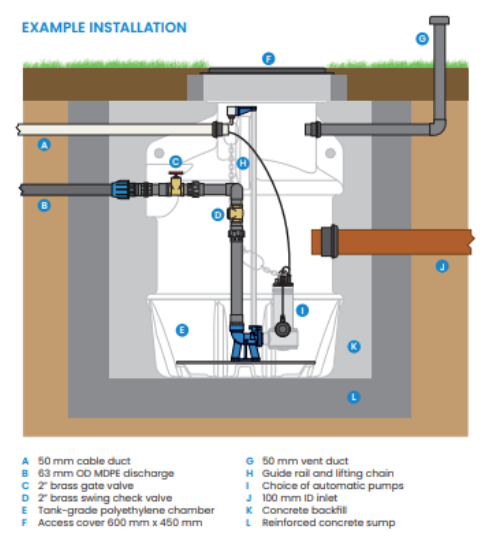

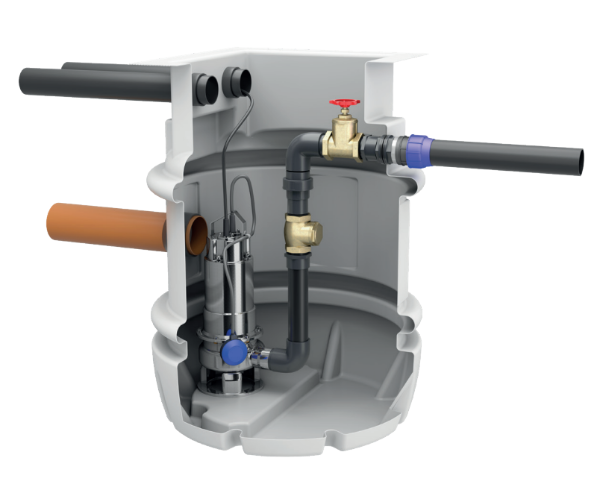

Foul water pump stations are specifically designed to collect and pump foul water (wastewater from toilets) and grey water (from hand basins, showers, and baths) from locations where gravity drainage is not possible or practical, such as basements, below ground structures, or ground floor extensions. The system temporarily stores the wastewater in a chamber and then uses a submersible pump to lift and discharge the water to a higher level, allowing it to reach the main sewer or drainage system.

These foul water pump stations are robust, reliable, and often feature pre-assembled internal pipework, non-return valves, and are manufactured from durable materials to withstand hydrostatic forces in high water table applications. They are not suitable for collecting groundwater from cavity drained systems and may include additional features such as battery backup, high-level alarms, and remote monitoring for enhanced operation and protection.

KEY FEATURES

- Chamber volume flexibility

- Vortex impellor for high flow rates

- 60° benching

- Compact chamber for limited space installations

- Ideal for an extension, outbuilding, basement or similar

- Variable inlet positions to suit site

- A range of alarms and remote alerts are available offering peace of mind

- Quick and simple to install

SPECIFICATIONS

This system complies with:

- BS EN 12050-2:2015 Wastewater lifting plants for buildings and sites. Lifting plants for faecal‑free wastewater.

- BS EN 12050-3:2015 Wastewater lifting plants for buildings and sites. Lifting plants for limited applications

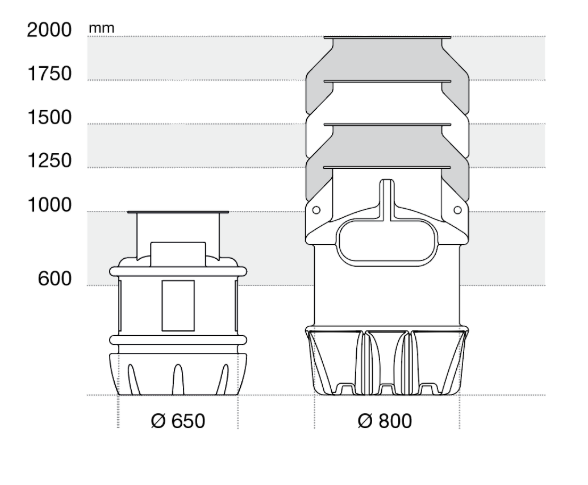

Tricel 650

- Up to 165 litre storage capacity

- One free-standing automatic pump

- Flexible inlet positions

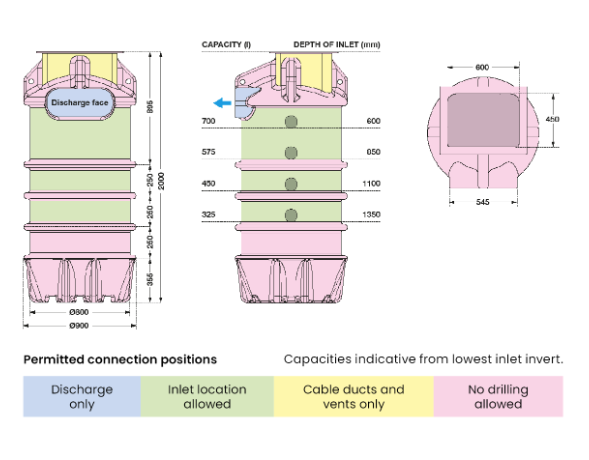

Tricel 800

- Up to 700 litres storage capacity depending on choice of chamber size

- One pedestal-mounted automatic pumps

- Flexible inlet positions

Tricel Twin 800

- Up to 700 litres storage capacity depending on choice of chamber size

- Two pedestal-mounted automatic pumps

- Flexible inlet positions

Choice of chamber sizes

The 800 dismeter Packaged Pumping station is available in 5 depths, 1000mm, 1250mm, 1500mm, 1750mm, and 2000mm.

REQUEST A QUOTE

Ask for a free quote today by clicking the link below

CONSULT THE DATASHEETS

Learn more about our Packaged Pumping Systems

Packaged Pumping Systems Datasheets

Foul water Pumps

Treated & Surface water pumps

- SumpFlush Twin 800-1250

- SumpFlush Twin 800-1250 cw Timer Control Panel

- SumpFlush Twin 800-1500

- SumpFlush Twin 800-1500 cw Timer Control Panel

- SumpFlush Twin 800-1750

- SumpFlush Twin 800-1750 cw Timer Control Panel

- SumpFlush Twin 800-2000

- SumpFlush Twin 800-2000 cw Timer Control Panel

- SumpFlush HP Twin 800-1250

- SumpFlush HP Twin 800-1250 cw Timer Control Panel

- SumpFlush HP Twin 800-1500

- SumpFlush HP Twin 800-1500 cw Timer Control Panel

- SumpFlush HP Twin 800-1750

- SumpFlush HP Twin 800-1750 cw Timer Control Panel

- SumpFlush HP Twin 800-2000

- SumpFlush HP Twin 800-2000 cw Timer Control Panel

Pump Case study

key features

High quality

At Tricel, we provide long-lasting & high quality sewage pumping stations.

Quick delivery

Need a sewage pumping station for a project? Timely delivery is a key priority for us.

easy install

Effortless installation with an intuitive control panel.

50 YEARS IN BUSINESS

A highly successful multinational corporation with over 50 years’ valuable industry experience

SEWAGE TREATMENT PLANTS

Plants available for all capacities, from 1PE up to 50PE. Free advice on request.

FAST DELIVERY

On-time delivery is a core requirement of our successful business operations

Frequently Asked Questions

Packaged pumping systems are pre-assembled systems used to pump wastewater to a sewer or sewage treatment plant where gravity drainage is not possible or economical to install. They are fully automatic units with all necessary components installed in a chamber (as well as external control panels and alarms if applicable) making them easy to transport, install and service.

Any application where gravity drainage of wastewater is not possible or economical to install.

Sewage pumps should run intermittently. The waste rises in the chamber until it reaches a set level upon which a float switch will activate the pump. Once the waste level has fallen sufficiently the pump is switched off.

The main considerations when buying a packaged pumping systems are the wastewater type, inflow rate, storage requirements and the height and length of the discharge pipework.

If in doubt, get in contact with our our Sales Team for advice.

Packaged pumping systems should be serviced regularly by a trained engineer. Provided they are well maintained they will last a long time. Individual components, including pumps, will wear down over time and will need replacing eventually. The rate of wear depends on how often they are used and whether the system is abused (flushing incompatible items). Our systems are designed to be easy to maintain.

Correctly specifying the chamber and pumps will ensure that the system operates less frequently and with less effort. An under-specified system will have to work more often and harder, requiring more electricity. It also increases wear on the pumps so they will need to be replaced more frequently.

Inflow of surface water or groundwater cannot be controlled so if there is a power cut or the system fails there is a risk of flooding. Consequently, we do not recommend that foul systems accept surface water and groundwater.

A second pump provides a backup in case the primary pump fails or becomes blocked. For surface water and groundwater applications where inflow cannot be controlled twin pump systems are recommended in accordance with BS 8102:2022 and PCA guidelines.

Twin pump systems also offer increased life spans due to reduced wear on the pumps and internal components.

Get in touch